Spray System for Midstream Chemical Processing

Chemical processing industries must obtain efficient and clean operations when dealing with corrosive and toxic chemical materials. These chemical materials are going through a range of refinement machinery, as they travel along pipes into holding tanks, mixing tanks, and other equipment used in midstream production lines. Midstream processes also involve using air cooling and humidification equipment. Here at Lechler, we understand the importance of using an efficient and cost-effective spray system for midstream chemical processing. We evaluate your specific processing methods and develop spray nozzle solutions that are a better fit for your operations. Learn more about spray system components and challenges faced in midstream chemical processing.

Key Components of a Spray System for Midstream Chemical Processing

Spray system components vary based on the size of the tank or the specific application. For vertical slender tanks, tank lances have a sled profile to fit within tanks while equipped with a free pinned spray nozzle. This setup allows the nozzle to spray wash water to reach both the top and the bottom of the tank as well as along the edges of the side walls. These nozzles accommodate flow rate and desired droplet sizes while lowering water consumption.

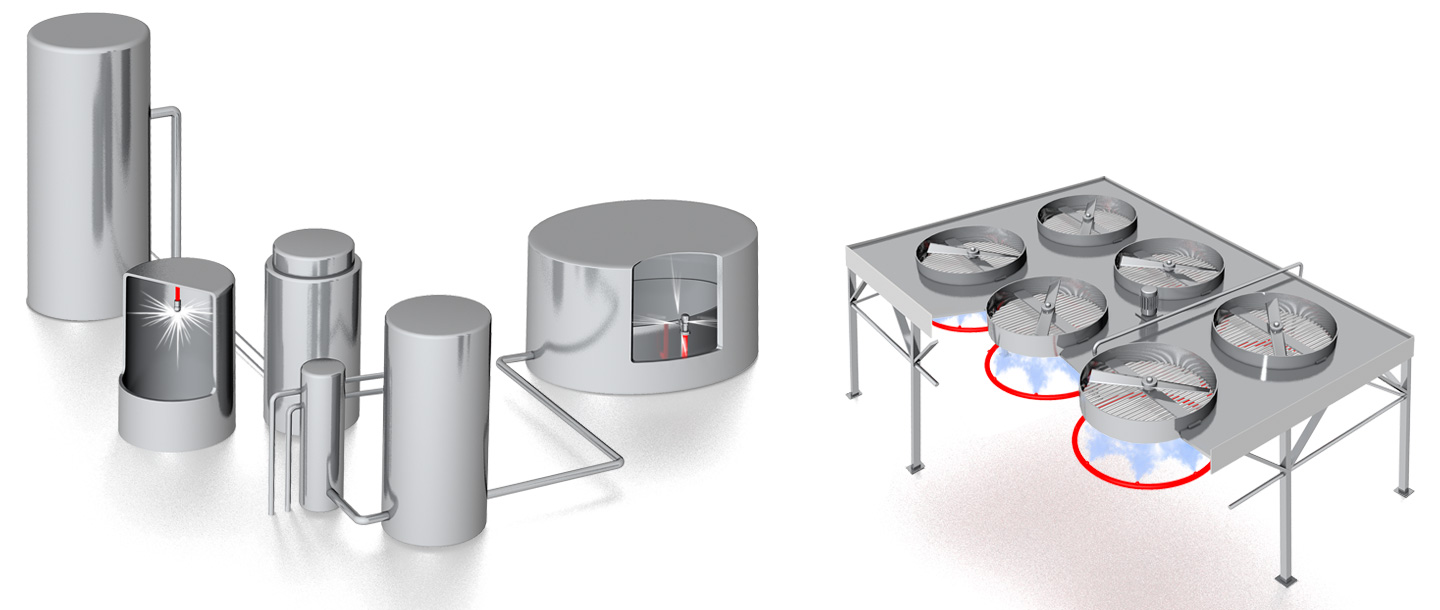

For larger tanks or for small tanks that have persistent chemical or dirt buildup, high-impact tank cleaning machines provide effective cleaning solutions. The nozzles provide larger jets of water and can handle higher temperatures at 215 psi. These jets of water are capable of reaching the sides of the large tanks to remove chemicals, dirt, and grime accumulation. For small tanks that have large deposits, the high-impact spray nozzles can knock off the deposits to the bottom of the tank without damaging the interior surface of the tank's metal sides.

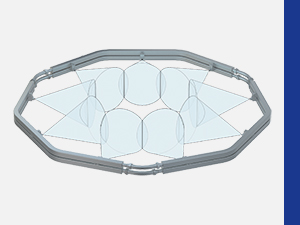

Another key component required in midstream chemical processing involves cooling the air and maintaining the appropriate humidity levels. When pushing air or gas through large fans, water droplets become injected into the airflow as it cools the air and removes exhausted gasses by way of evaporation. Spray headers located below the working fans' intake channel and push fine droplets inward in the oval/round opening. The gas or air passes through the generated mist as the evenly distributed spray effectively removes the heat and provides the right amount of humidification for processes.

Common Challenges and Solutions in Midstream Chemical Processing

Challenges faced in midstream chemical processing consist of maintaining worker safety while cleaning tanks and equipment that are often enclosed systems. Manual cleaning and washing activities often require significant downtimes while workers must enter into tanks that can contain dangerous chemicals that are corrosive and toxic.

To minimize accidents and keep operations running at a steady pace, employing an automatic spray system for midstream chemical processing speeds up the process while not having the worker directly involved in the task. Automatic spray systems minimize chemical cross-contamination while ensuring that every surface is washed and rinsed cleaned. It reaches the crevices at the desired velocity and flow rate for even water droplet distribution. At the same time, it uses less water while still providing efficient cleaning solutions, conserving water usage and lower utility costs.

Tips for Maintenance and Cleaning

Creating cleaning and maintenance programs for your spray nozzle systems ensures that the nozzles will work at full capacity and that any issues are repaired in a timely manner. The programs should be tailored based on the frequency of use for the spray nozzles as well as the amount of dirt and chemical buildup that occurs during daily processes. Nozzles should be inspected and cleaned to remove clogs. They should also be inspected for cracks, excessive wear and tear, erosion, and corrosion.

For more information regarding our spray nozzle technologies, contact Lechler.

Examples engineered solutions | Examples spray nozzle solutions |

Tank lances

Spray headers

| High impact tank cleaning machine - series 5TA/5TB/5TM

Free spinning tank cleaning nozzles - series 569

Cluster nozzles - series 502/503

More |

Contact

For additional products, please refer to suggested literature.