Pulp and Paper Industry

Spray nozzles for all areas of production

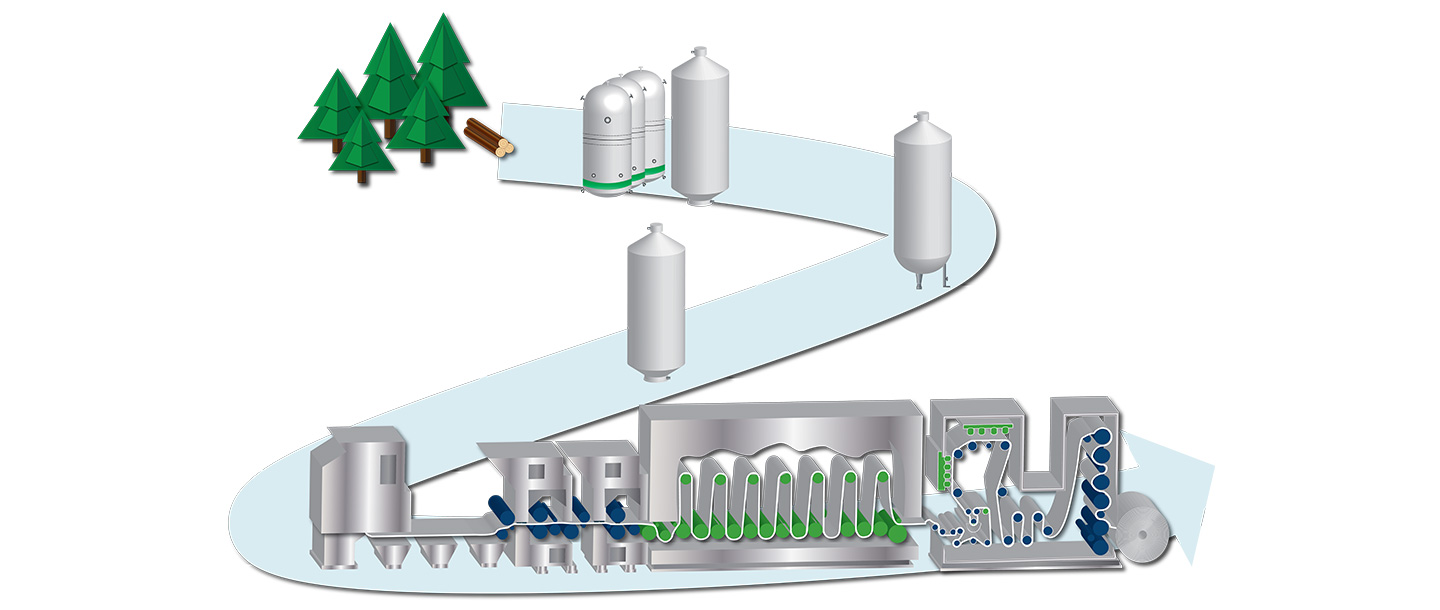

The pulp and paper industry is closely connected. The process of paper production is divided into two steps: The first step consists of processing wood to pulp, which is further processed into paper. Lechler offers atomizing technology for many processes of the whole production line. Let us know where we can help you improve – talk to us.

Lechler spray nozzle applications for pulp and paper production

Pulp production

The pulp for paper is produced from debarked shredded wood. Lignin of the wood, and other non-fibrous parts are almost completely removed in a cooking process. Lignin residues are removed in subsequent bleaching processes. Large quantities of process water and chemicals are required for the various processes. Costs can be saved by optimizing the nozzles to the process.

Lechler spray nozzle applications for pulp production:

- Wood preparation

- Hydromechanical debarking

- Stone and dirt separation

- Grinding stone and pulp preparation

- Lubrication of the saw blades

- Pulp path

- Roller cleaning

- Pulp washing

- Tank cleaning

- Pulp Drying Plant

- Paper recycling

- Filter cloth cleaning

- Drum filter cleaning

- Defoaming

Paper production

Lechler spray nozzle applications for paper mills

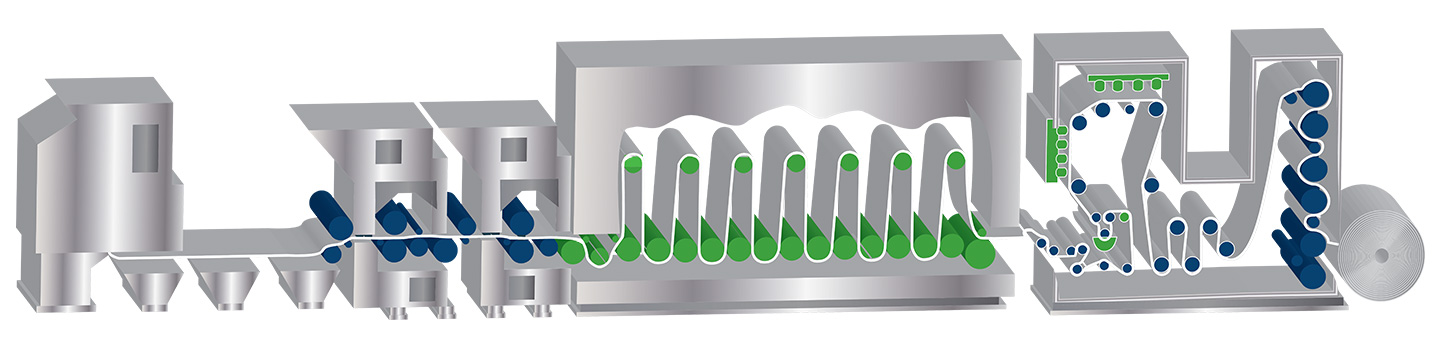

Sections of a paper mill

In the diagram above, the most common sections of a paper machine are shown, but these can vary, depending on the mill. The general layout can be divided into the following sections:

- Headbox (wet-end)

- Press section

- Dry end

- Coating (paper finishing) and rolling up

Engineering your spray solution

The production of paper requires a large consumption of water and chemicals. Lechler spray nozzles use fewer liquids and resources, which reduce overall costs. Product quality is maintained and production can run efficiently with less interruptions.

Last section of the paper handling process: rolling up of the paper.

Last section of the paper handling process: rolling up of the paper.