Emission regulations are becoming increasingly strict and for this reason cement plants are required to find more effective ways at reducing emissions. For years, Lechler has specialized in nozzle lances and systems for DeNOx applications to help reduce emissions in cement plants.

![]()

During the production of cement, harmful nitrogen oxides (NOx) can be emitted into the air, depending on the different process variables used. NOx is detrimental to both human health and the environment because once it is emitted into the air it can become a component of smog and acid rain. These can cause pulmonary and respiratory issues, as well as destroying vegetation and plant growth.

In order to control NOx at cement plants, selective non-catalytic reduction SNCR systems are used. For the non-catalytic reaction, a reagent (mostly aqueous ammonia) is specifically injected in the area of the optimum temperature window of approx. 950 - 1.050°C . Exceeding or falling below the temperature window will lead to additional NOx formation or an increase in the NH3 slip. The efficiency is reduced in both cases. In addition to the optimum temperature, parameters such as droplet size and velocity are also of crucial importance. Only with the appropriate nozzle and the right control concept can the droplets penetrate deep enough into the flue gas flow to ensure optimum distribution of the reducing agent in the flue gas flow.

SNCR applications in the cement industry at a glance

![]()

Lechler offers a wide product portfolio of nozzles and lances suitable for reducing NOx emissions at cement plants. Our engineers can design and manufacture in accordance with your process requirements to ensure your system is reliable.

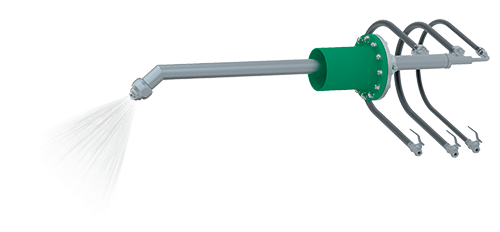

Laval Twin Fluid Nozzles

These nozzles atomize liquids as a fine full cone and work on the super-sonic principle. By changing the air/liquid ratio, the droplet size and the droplet spectrum can be adapted within a wide range for special applications.

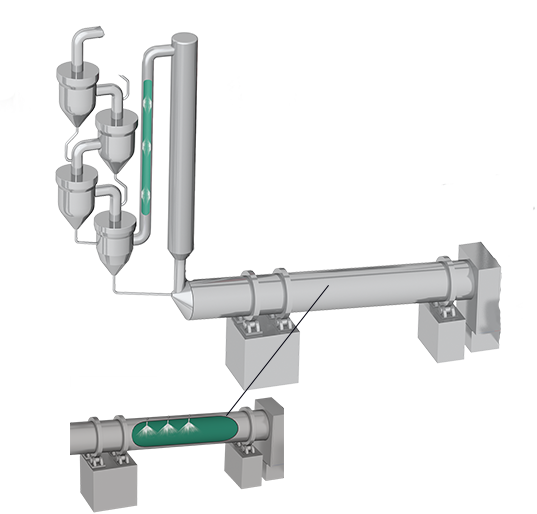

Nozzle Lances

Our nozzle lances are designed to ensure optimal spray placement and alignment in flue gas ducts. The nozzles themselves have a low-maintenance design and can be quickly cleaned or exchanged with minimal effort. Our engineers take into consideration your process requirements for individual adaption.

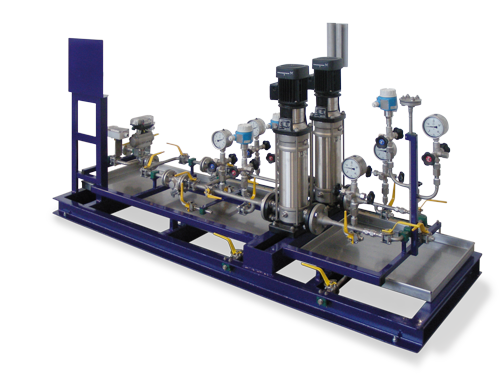

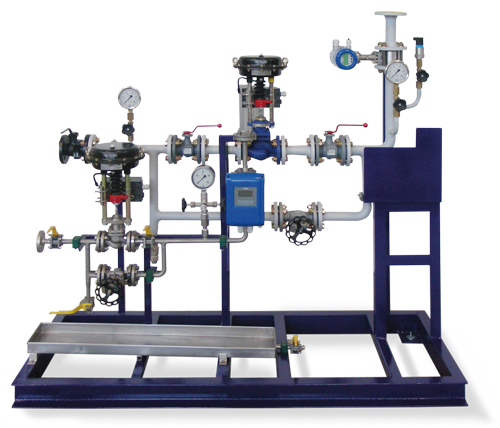

Pump & Control Skids

Lechler offers a system solution tailored to your application and plant-specific conditions. We use only high-quality components from renowned manufacturers for our valve skid units. If you choose a system with a control, you will get a complete solution for your gas conditioning requirement from a single source.