VarioClean – NOx (heSNCR) injection system

The denitrification solution that grows with you.

The limit values for NOx emissions and ammonia slip (NH3 slip) are expected to be reduced further in the coming years. To enable a profitable production of cement all the same, processes must be observed and optimized with intelligent control strategies. For this purpose, Lechler has joined forces with STEAG to develop an SNCR concept that reliably ensures compliance with the limit values in force: VarioClean - NOx.

Three steps for any requirement

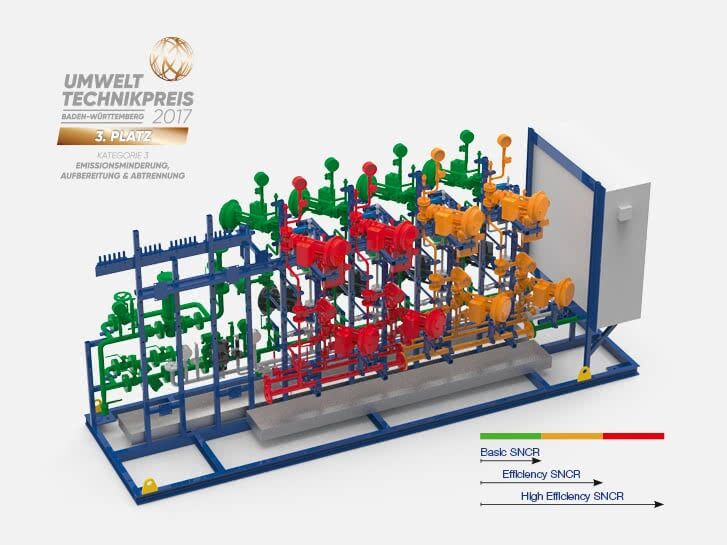

Depending on (what is required by) the legal situation, the modular system VarioClean - NOx can be flexibly upgraded across the three configuration levels. Basic, Efficiency and High Efficiency SNCR. The base frame and the base modules are identical for all three configurations. The difference lies in the number of lances and injection levels, as well as in the software and sensor packages for the successful control of all necessary influencing factors.

Basic SNCR (green level)

The control of flue gas denitrification is based on a NOx measurement at the flue. Both aqueous ammonia and urea can be used as a reagent for the denitrification. All existing lances are controlled by the conventional control – depending on the NOx concentration measured. The Basic SNCR is primarily used where comparatively high NOx limit values or no limit values must be observed for the NH3 slip and there are very stable temperature conditions. The base frame of the valve skid unit and the installed fittings are designed for later upgrading. Further lances can be integrated using additional distributor pieces. Since individually controllable lances can be used from the start, a Basic SNCR system can be extended to both of the next configurations without any problems.

Efficiency SNCR (green + yellow level)

In the case of higher requirements in terms of the limit values to be complied with and less stable temperature conditions, the "efficiency SNCR" (eSNCR) with a larger number of lances is ideal. The lances are installed on at least two levels and each lance is individually supplied with the reagent. In addition, a software-based "intelligent controller" is connected with the PCS via an interface and supplied with current process signals. This allows the NOx concentration in the raw gas to be estimated and thus enables a more accurate and more economical dosing of the reagent.

High Efficiency SNCR (green + yellow + red level)

The "high efficiency SNCR" (heSNCR) meets the highest NOx reduction demands while at the same time keeping reagent consumption to a minimum. It has further lances, which are normally installed on at least three different levels. The control is extended to include online CFD simulating the temperature and flow conditions in the injection area. Together with the estimated amount of NOx in the raw gas and the NOx concentration measured in the clean gas at the flue, then spray behavior of each lance can be individually controlled for an optimal use of the reagent.

Advantages

- Systems grow with the legal requirements

- No unnecessary investments

- Modular design in three upgradable configuration levels

- Optimal reagent use resulting in reduction of operating costs

- High NOx-Reduktion (suitable solutions for requirements of differing complexity)

- Low NH3slip (adapted solutions for reduction of NH3 slip)