How does a Spray Ball work?

A spray ball cleanses the tank or container by creating a continual series of fluid distribution through each of the hole design patterns. The water or cleaning solution is forced out of the ball via powerful pressure creating a jet stream, the jet stream plunges into the tank wall, fans out, and cleans as gravity pulls the suds down to the bottom of the tank.

What Type of Spray Ball do You Need?

Several factors should be considered before purchasing stainless steel spray balls. You will want to consider the size of the container or tank which needs to be cleaned. You must consider the spray hole or slot design pattern to ensure you get the coverage you need. You need to consider the connection type the spray ball will connect to, as well as the type of soil that is being cleaned.

What’s the Difference between Static vs. Rotating Spray Balls?

Static spray balls are just that, they are stationary, and utilize high-volume, but low-pressure cleaning. The cleaning occurs mainly by creating a wash effect by the solution flowing down the sides of the container. [1] Since static spray balls do not rotate, they require a comparatively large amount of liquid in order to generate turbulent flow. The benefits of the static spray ball include: no moving parts, self-draining, easy inspection and ideal of high hygienically focused tanks.

Rotating spray balls, on the other hand, consist of a low-volume, high pressure spray as the nozzle turns. The spinning nozzle projects the cleaning solution through the interior of the container through a rapid, repetitive stream. The benefits of rotating spray balls is they generally clean faster and better than static spray balls. One of the shortcomings of the rotating spray balls is they generally reach a smaller area. These are ideal of diameters of about 6 ft or less.

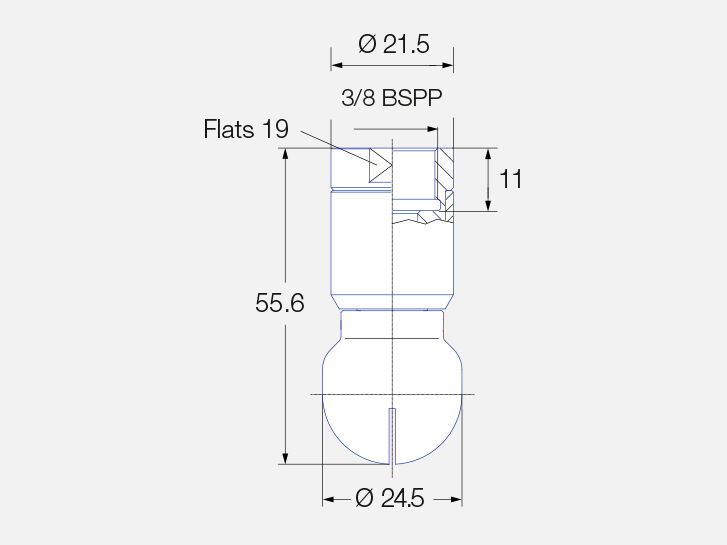

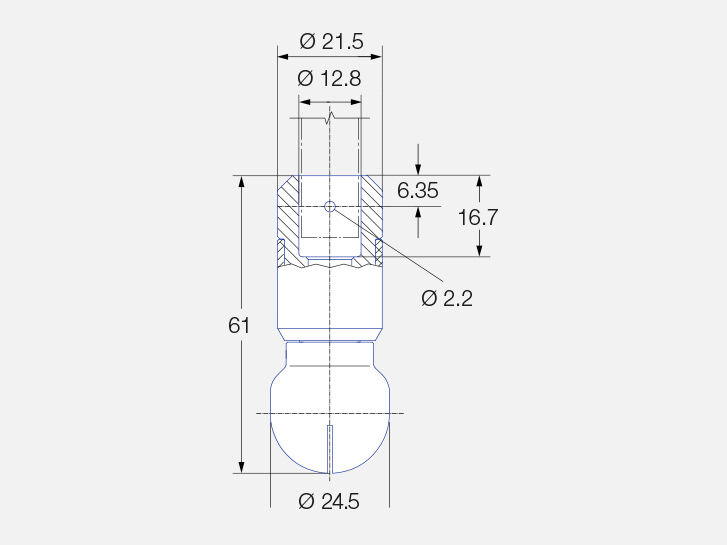

Rotating Cleaning Nozzle “MicroSpinner”

The “MircoSpinner” is a new and innovative design. Rather than a series of dozens of tiny holes, the “MircoSpinner” contains a multi slot design. This nozzle is extremely effective for cleaning, and not only that, but it is also reliable and durable. The “MicroSpinner” components are made up of stainless steel and Hastelloy.

The “MicroSpinner” is made to withstand high water and cleaning solution temperatures of 284˚F (140˚ C), and the recommended pounds per square inch is 30 PSI. Compared to some of our static spray balls, the size tank ideal for the “MircoSpinner” is smaller, as it is most effective for about 6 ft and less in diameter.

This nozzle is available in 3/8” female NPT threaded or the ½” slip-on connections.

Controlled Nozzles

We also provide an assortment of controlled rotation nozzles, gear controlled nozzles, and all the accessories you need for cleaning your tanks. Click here to see other products you may need to complete your tank and equipment cleaning jobs.