High Pressure Tank Cleaning Isn't Always Efficient

Multiple decisions play a role in maximizing efficiency during the process of cleaning commercial tanks and equipment. Choosing to use spray nozzles instead of manually cleaning is important. Selecting the ideal tank cleaning device for your application is equally critical. Rotating or static? Which nozzle is best for a tank of my size and how many nozzles should I use?

However, once you’ve determined the very best option for your application, maximizing cleaning efficiency is not over. Specific details, such as pressure and impact, are equally important for optimal efficiency. Below, we explore one seemingly small, yet important aspect in tank and equipment cleaning: operating pressure and how it relates to spray impact.

Impact and Pressure

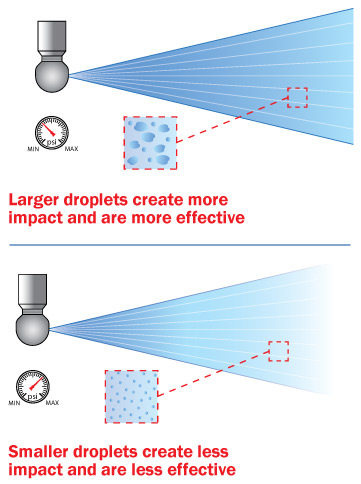

When cleaning the internal surface area of a tank, rotating cleaning nozzles deliver the greatest cleaning efficiency. When ran properly these nozzles are able to produce large droplets which strike the sides of the tank at high speeds. This is achieved when two dynamic factors work simultaneously: operating pressure and the distance between the nozzle and the internal surface of the tank.

For rotating nozzles, pressure and impact have no linear relationship. Supply pressure simply influences rotation speed. Increased pressure equates to increased rotation speed.  As counterintuitive as it may seem, high pressure tank cleaning is not always ideal, because higher pressure does not equate to higher impact. In fact, if operating pressure or distance between nozzle and surface aretoo great, the fluid will break down into smaller droplets, similar to a mist.

As counterintuitive as it may seem, high pressure tank cleaning is not always ideal, because higher pressure does not equate to higher impact. In fact, if operating pressure or distance between nozzle and surface aretoo great, the fluid will break down into smaller droplets, similar to a mist.

Examining Recommended Pressure and Maximum Impact

Lechler nozzles are designed to operate with optimum impact at the right operating pressures. Some function under high pressure, others operate under lower pressures. Below, we examine various operating principles for a few specific nozzles, along with their ideal operating pressures.

Free-Spinning Nozzles

Free-spinning nozzles are powered by the cleaning fluid. The spray head rotates as the fluid sprays, producing rapid-repetition impact, excellent for washing dirt from tank surfaces. This effect is best achieved at low pressures. A small selection of free-spinning nozzles that operate with incredible impact at low pressures include:

Series 566 “MicroWhirly"

Recommended operating pressure: 30 psi

Maximum temperature: 266 °F

This compact nozzle is excellent for cleaning in confined spaces

Series 594 “HygienicWhirly”

Recommended operating pressure: 45 psi

Maximum temperature: 212°F

Excellent for hygienic requirements and for applying foam.

Series 5MC “MicroSpinner"

Recommended operating pressure: 30 psi

Maximum temperature: 284°F

Built for tanks with smaller openings

Controlled-Rotation Nozzles

Controlled-rotation nozzles are also driven by fluid flow. However, unlike free-spinning nozzles, a turbine wheel with an internal gear is used to control the pattern of rotation. Even at higher pressures, the spray impact is not compromised because larger droplets can still be achieved. Two excellent examples of controlled-rotation nozzles are listed below:

Series 5S2/5S3 “XactClean HP+”

Recommended operating pressure: 75 psi

Maximum temperature: 203 °F

Gear Controlled Nozzles

Built for battling persistent soiling, gear-controlled nozzles function with extremely high impact under extremely high pressures. High-grade gear units work with measurably controlled rotation and run on two axes. These powerful jets sweep the entire tank surface by utilizing a specific pattern. Due to their extraordinary impact, they are often utilized in the food and beverage, chemical, petrochemical, and paper industries.

Series 5TB “IntenseClean Hygienic:”

Recommended operating pressure: 75 psi

Maximum temperature: 203 °F

Weight: 8.8 lbs

Series 5TM

Recommended operating pressure: 75 psi

Maximum temperature: 140 °F

Weight: 16.5 lbs

Lechler: Engineering Your Spray Solution

For over a century,Lechler has been engineering evolutionary spray solutions for a wide variety of industries, serving markets from food and beverage, chemical, steel, and power generation. We are more than just a nozzle manufacturer, however. We provide custom engineered spray solutions. We offer extensive resources to expand your spray application knowledge. We are here to guide your business into the most efficient and effective organization it can be.

Get in touch with us today at (800) 777-2926 or via our online contact form to begin a conversation. We look forward to offering more information!