Industry owners know the importance of maintaining a clean and sanitized tank. Unwanted chemicals or bacteria can destroy the next production batch, resulting in lost revenue, production time and materials. To some this may seem like a daunting task but it does not have to be. With the right rotational spray device you can efficiently clean your tank saving you time and money. Learn more about Lechler's rotational spray solutions.

If your goal is to efficiently clean your tank in less time then Rotational spray devices solutions are the best option and here is why:

IT'S ALL ABOUT IMPACT

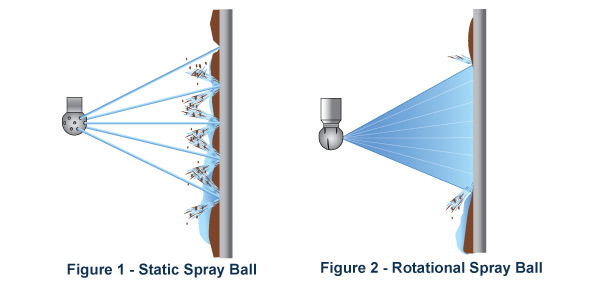

Impact, droplet size and spray coverage are critical to efficiently cleaning the entire surface area of a tank. The image below shows a static spray ball with a solid stream and a controlled rotating water head with a flat fan spray. The solid stream in the static spray ball is powerful however, due to its concentrated stream flow it only penetrates one area. The residual surface areas are cleaned by cascaded water wash, commonly known as shear stress.

The controlled rotating water head produces a flat fan spray and the droplets produced are larger and strike the tank wall at higher speed. The rotation allows the sprays to cover the entire surface area of the tank, unlike the static spray ball.

It depends on what size tank you have and what type of soil you are trying to clean. Lechler offers various high impact tank cleaning nozzles for different tank sizes.

If you are unsure which nozzle would be best for your application we can help! Lechler’s team of in house engineers utilize a tank simulation software which is the perfect tool for selecting the right nozzle with exact placement inside your tank.