Multi Channel Air Nozzles

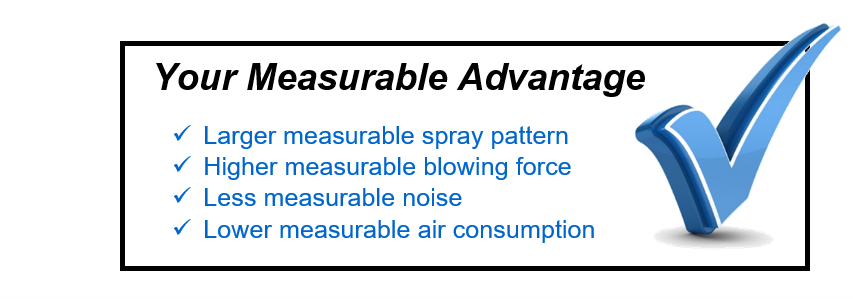

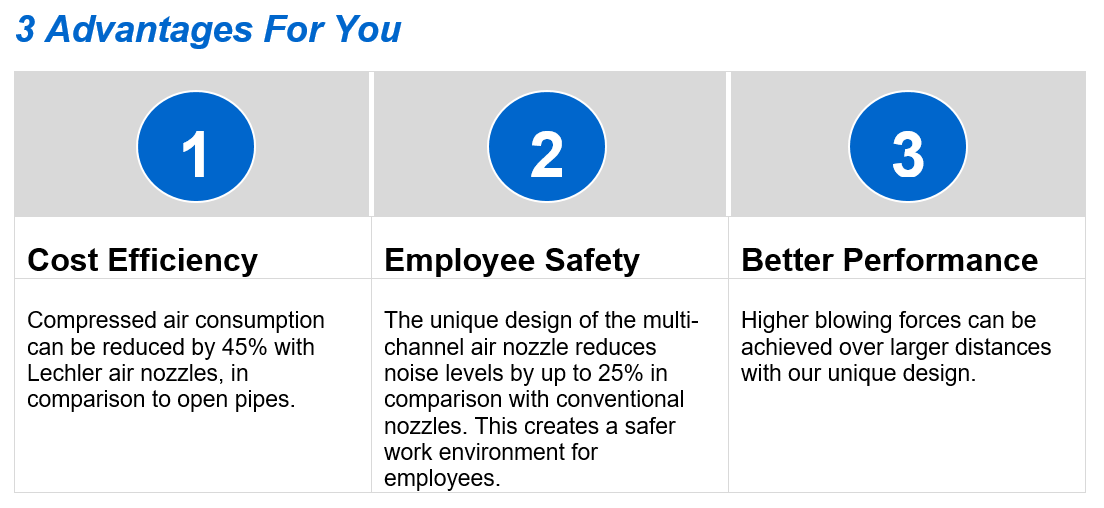

Compressed air is widely used in many industries because air is essential for cooling, drying, cleaning, and performing other tasks. At the same time, compressed air can cause additional costs by creating high noise emissions, especially with conventional air nozzles. For this reason, Lechler has designed the multi-channel air nozzle, which reduces air consumption by up to 45%. The unique design of our nozzles reduces the noise significantly, which makes it a safer work environment for your employees.

Let’s explore some basic fundamentals of multi channel air nozzles.

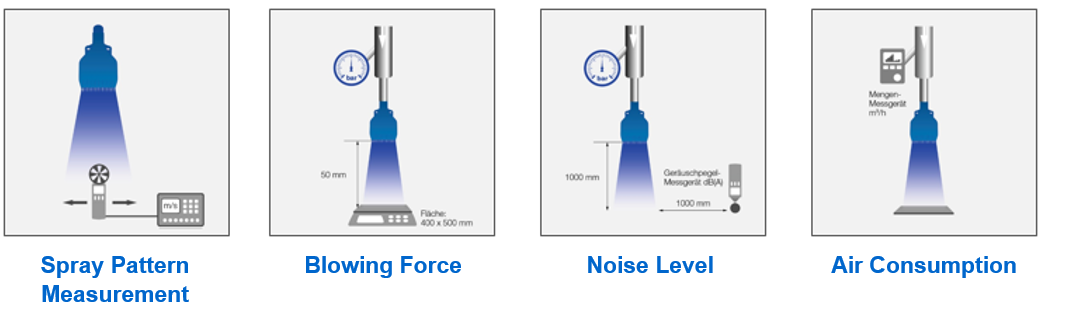

Spray Pattern Measurement

In order to measure the spray pattern, the nozzle is clamped in a special fixture. An anemometer moves through the sprayed gas and this is where the wind speeds are measured. The compact design and unique form of our air nozzles allow for extremely high speeds and larger throw distances.

Blowing Force

Our measurements indicate that Lechler multi-channel nozzles achieve a high blowing force even at large distances. As a result of this, our nozzle technology can be used for several types of applications, where conventional nozzles are limited.

Noise Level

Conventional air nozzles simply blow air through a hole, which creates turbulence and results in very loud harmful noises. These loud sounds can be destructive to workers, while impairing hearing and performance. The design of Lechler’s multi-channel air nozzles reduce the turbulence, while guiding the air uniformly into arranged air channels. A variey of Lechler’s air nozzles have been tested to meet OSHA requirements.

Air Consumption

Nozzles from Lechler are designed so that less compressed air is required without compromising performance, unlike conventional nozzles. As a result, our products help to make production processes more efficient and environmentally friendly.

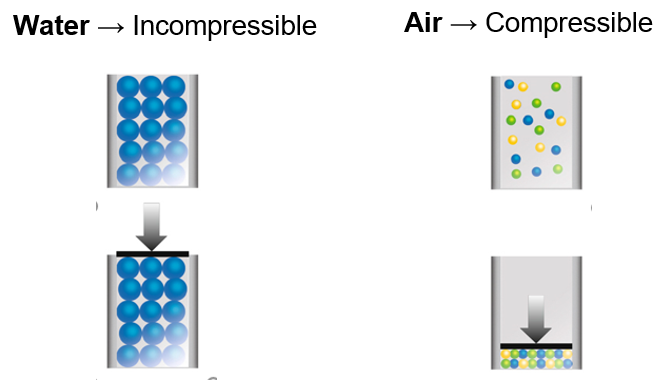

The output of gases is fundamentally different to the output of liquids. Gases are compressible fluids, whereas liquids are considered incompressible fluids, as seen in the chart below. Gases can be supplied with practically all nozzles that can also be used for atomizing liquids. However, due to the compressibility and lower density of gases, gas sprays cannot be formed in the same way as with liquids. Gases tend to generate a significantly increased noise level under various conditions, such as pressure and nozzle design.

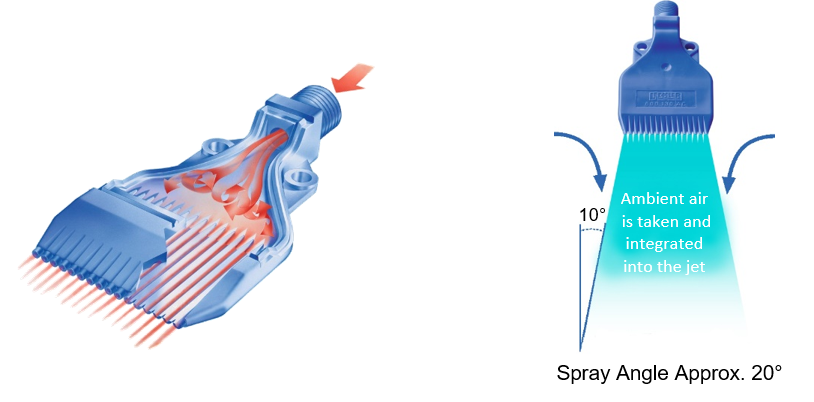

The specially designed multi-channel nozzle reduces turbulence and provides a uniform, targeted and powerful airflow. The uniquely shaped orifices guide the supplied air uniformly into arranged air channels to ensure optimum flow behavior. As a result, this reduces noise and air consumption.

Air is also discharged at a specific angle. However, this is not comparable with that of liquids. Air expands when it is discharged from the nozzle orifice, which leads to expansion of the jet. The spray angle is normally approx. 20°.

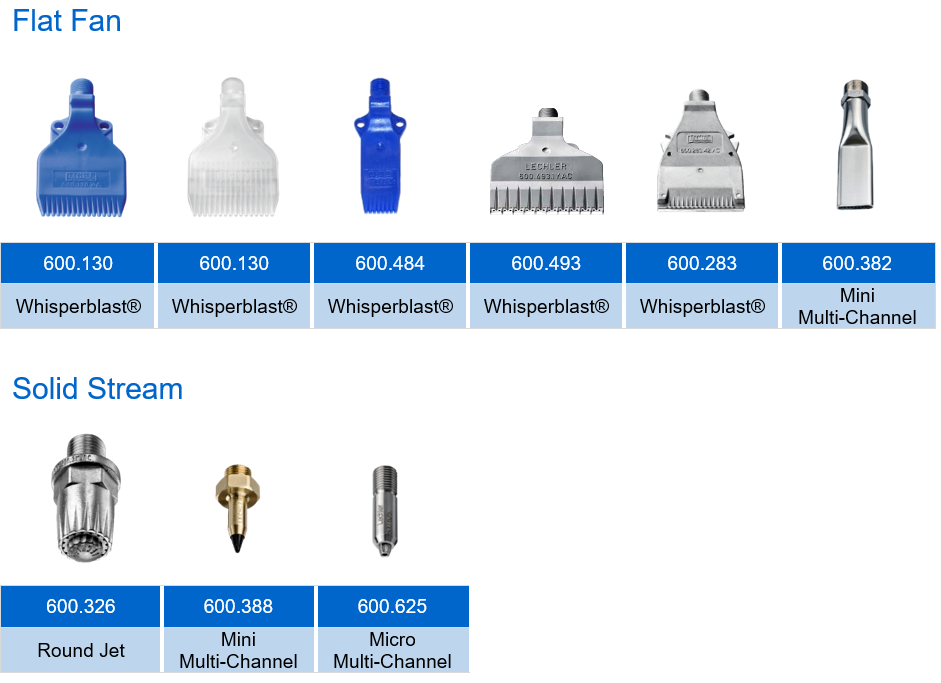

Lechler offers a complete line of multi-channel air nozzles suitable for all types of applications. Our nozzles are preferred over conventional air nozzles because of their low noise levels meeting OSHA requirements. You can find our multi-channel air nozzles being used in multiple industries, including food and beverage, where FDA compliant materials are required. Our engineers can also custom design and fabricate air nozzle headers if more than one nozzle is required in the given process.

If you’re targeting a specific area for cooling, cleaning, blowing, sorting or drying, our engineering experts are here to assist with your application.