Mist eliminators – Functional Principle

Mist eliminators differ on the one hand in the direction of flow and on the other hand in their degree of separation. Accordingly, there are different types of mist eliminators.

The Functional Principle – vertical or horizontal gas flow

Various vertical and horizontal types of Lechler high-performance mist eliminators are available, depending on the direction in which the gas is required to flow. Where circumstances demand, it is also possible to provide separators for an oblique flow of gas. The choice of the suitable separator depends on the design of the plant and other requirements. The Lechler engineering staff wil ensure the right choice.

Mist eliminator with vertical gas flow

In vane-type mist eliminators with a vertical gas flow the baffle vanes are arranged horizontally or at a slight angle to the horizontal. Since the gas flows upwards in the opposite direction, it is necessary for the baffle vanes to be designed so that certain regions are bypassed by the gas flow.

Thus zones are provided in which the droplets can be collected without interaction with the gas. These zones also provide a secure diversion of the collected liquid from the surface of the vanes. This requirement can be met in various ways and in function of the profile and shape of the vanes.

As the liquid has to flow in the opposite direction to the gas, the film of liquid that forms on the vane has to be converted back to droplets. To prevent overstressing of the system by droplets being picked up and recirculated by the gas flow, these droplets must be substantially larger than those carried into the separator by the gas.

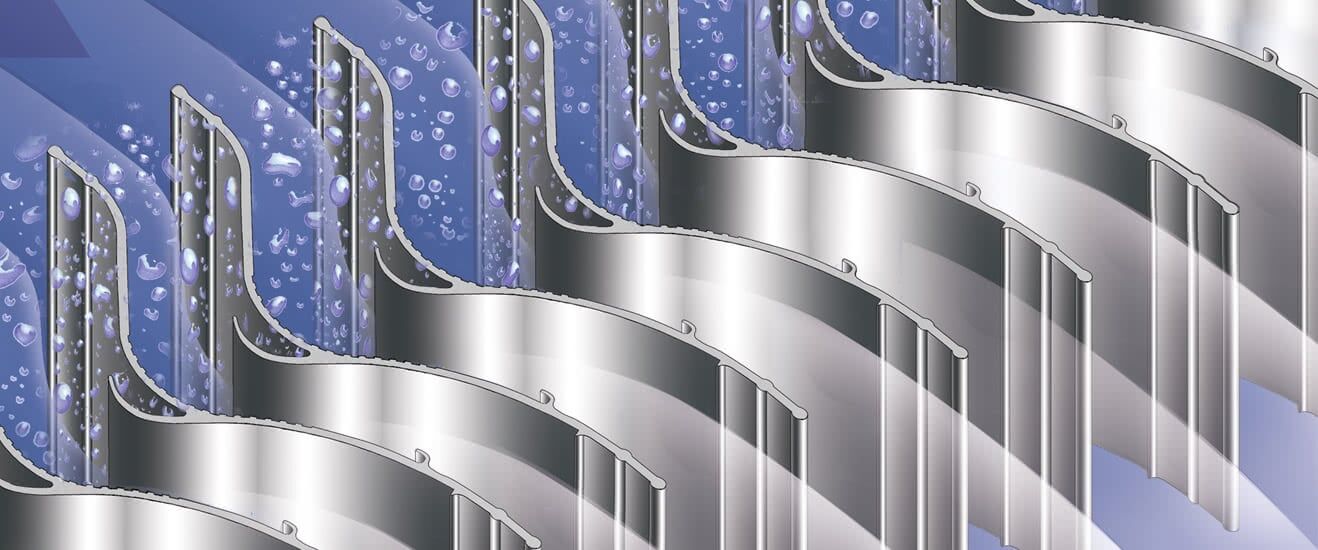

Mist eliminator with horizontal gas flow

Vane-type mist eliminators for a horizontal gas flow have a system of vertical baffle vanes. The provision for secondary separation is of a different design from that of separators for vertical gas flow. When the flow of gas is horizontal the baffles stand vertically and the liquid film that forms on them flows downwards by gravity. The provision of regions, before or behind the phase-separation chambers, that are bypassed by the gas flow, enable the liquid film to flow off the baffles without renewed contact with the gas.

The fact that the flow-off is assisted by gravity results in mist eliminators with a particularly high performance. Depending on the separator, gas-flow rates of up to 10m/s can be achieved. The baffles can be shaped for particularly satisfactory gas flow characteristics, therefore the pressure loss across such separators is remarkably now. To suit the needs of each particluar application, a choice can be made from a finely staged range of baffle-vane types with a simple or multiple gas-flow diversion.

The Functional Principle – Primary and Secondary Separation

Lechler vane-type separators work on the physical principle of inertia, and separation is thus effected in two stages: The primary separation and the secondary separation.

Primary separation

A flow of gas, laden with droplets, flows through a band of curved and specially formed baffle vanes. Forces of inertia act upon the droplets while these are subject to directional flow changes in the baffle vanes. These forces divert the droplets from the original gas flow. The geometry of the baffle vanes, the nature of the gas and of the fluid, and the size and initial locations of a particular droplet, determine whether the gas will carry it through the space between the baffle vanes, or whether it will come in contact with one of the separator surfaces. Droplets that under given conditions come 100% in contact with a baffle-vane and then join with others to form a film of liquid are designated "limit droplets" are separated at this stage. At the same time only a small number of the smaller droplets are separated at this stage. The proportion of droplets carried on by the gas flow is designated the "fractional degree of separation" and serves as a means of assessing the efficiency of a droplet separation system.

Secondary separation

The curvature and shape of the baffle vanes are such that the film of liquid formed on their surfaces as a result of primary separation is completely removed from the gas flow. This is generally achieved by the baffle vanes having specially-formed phase-separation chambers. Where droplet separators are concerned that have to work with as little pressure loss as possible. the baffle vanes are provided with a series of grooves that act as phrase separators.

Depending on the application, the phase separation chambers diffrer in shape and size. Apart from directional changes in gas flow, the number and form of the phase separation chambers considerably affect the pressure loss across the mist elimination system.

Beispielhafte Tropfenflugbahnen bei Horizontalabscheidern

Beispielhafte Tropfenflugbahnen bei HorizontalabscheidernOur products

Lechler Mist Eliminator Systems

Modular, compact, combinable and efficient.

The different Lechler Mist Eliminator Systems can be combined with each other, depending on individual requirements in relation to efficiency and space.