TankClean Software

Perfect reliable planning – TankClean simulation software

Planning the perfect cleaning process for your tanks can be a challenging prospect.

Identifying whether certain nozzles and systems will be able to reliably clean all surfaces of the tank cannot be decided with a simple visual inspection. Many tanks have built-in equipment such as agitators of baffles which can create spray shadows, as well as other issues which prevent a thorough clean.

When problems such as these are identified, our tank cleaning simulation software can provide huge benefits and insights to help you make the most of your cleaning system & procedure.

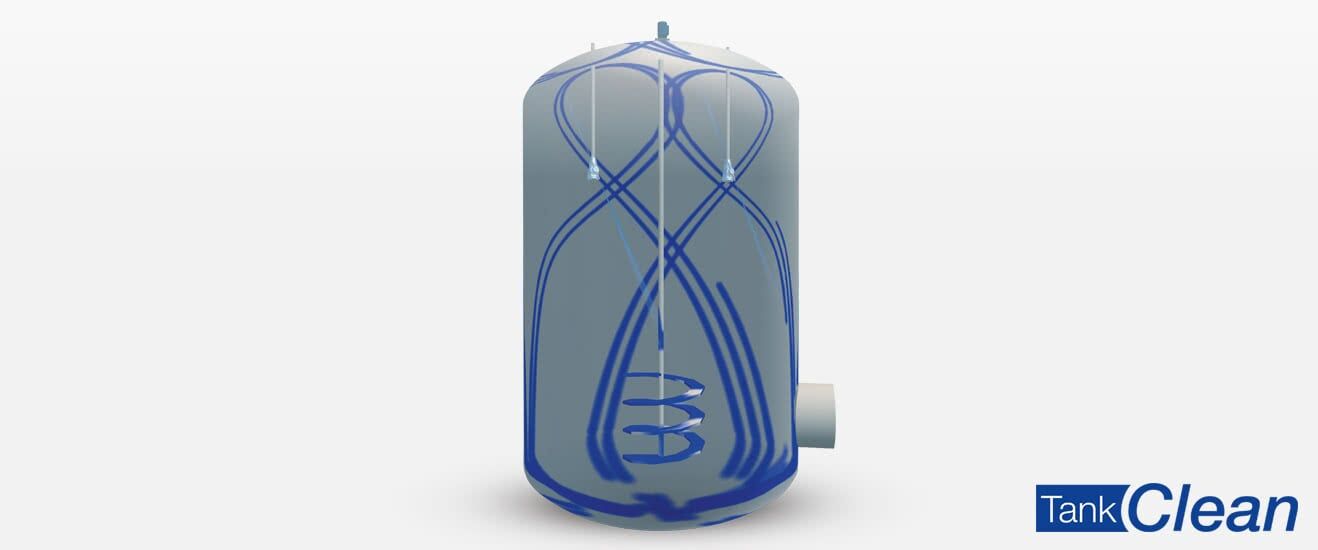

With our new and unique TankClean software, we can help you find the ideal solution for perfectly cleaning your tank. To do this, we replicate the tank geometry in the software and then simulate the spraying operation. Operation of all Lechler tank cleaning nozzles can be simulated – from the static spray ball to the high-impact tank cleaning machine. The result of the simulation is documented and provided in a PDF or video file. Simulation with TankClean can already be used as the basis for optimum cleaning in the planning phase of new tanks but is also suitable for optimizing existing tank cleaning processes.

Taking the Guesswork Out of Tank Cleaning

Be confident in your choice of the best product for your surface type and application. When determining your best tank cleaning solution, Lechler’s innovative new TankClean software can help find what is right for your tanks, your application, and your needs.

TankClean gives you the ability to simulate any Lechler nozzle type (from static spray balls to high-impact tank cleaning systems), providing a PDF overview or video simulation of how they work so you know what will clean your tanks most effectively before actually making a purchase. To create these simulations, TankClean software pairs data on average nozzle outputs and spray angles with highly accurate digital replications of the tank geometry, accurately depicting the size and shape as well as any internal instruments found.

With this revolutionary new technology at your disposal, operators are given actionable insight into the optimization of existing tank cleaning processes and guidance for the installation of new equipment.

What Can Lechler TankClean Software Do For You?

The TankClean Software User Interface – Clear & Intuitive

Step 1

Our software processes individual adaptation of tank geometries and built-in equipment. This means that however complex or unorthodox your tank engineering may be, our system can optimize a cleaning service for it.

Step 2

Lechler specializes in the selection of the best tank cleaning nozzles on a per-application basis. Our nozzle selection can be seen on our website. We have more than enough products for whatever service you may need; don’t let one piece of hardware be the roadblock between where you are now, and where you want to be.

Step 3

We then process a realistic simulation of the cleaning process. This means that anything and everything that will happen during the tank cleaning process will be shown in this simulation — with none of the realistic risk of the actual service. If something is not up to par before the time of actual service, our tank cleaning simulation software will be able to find it.

Step 4

After the simulation ends, our software documents the results for your review. Additional notes can also be added as aids for the upcoming cleaning process.