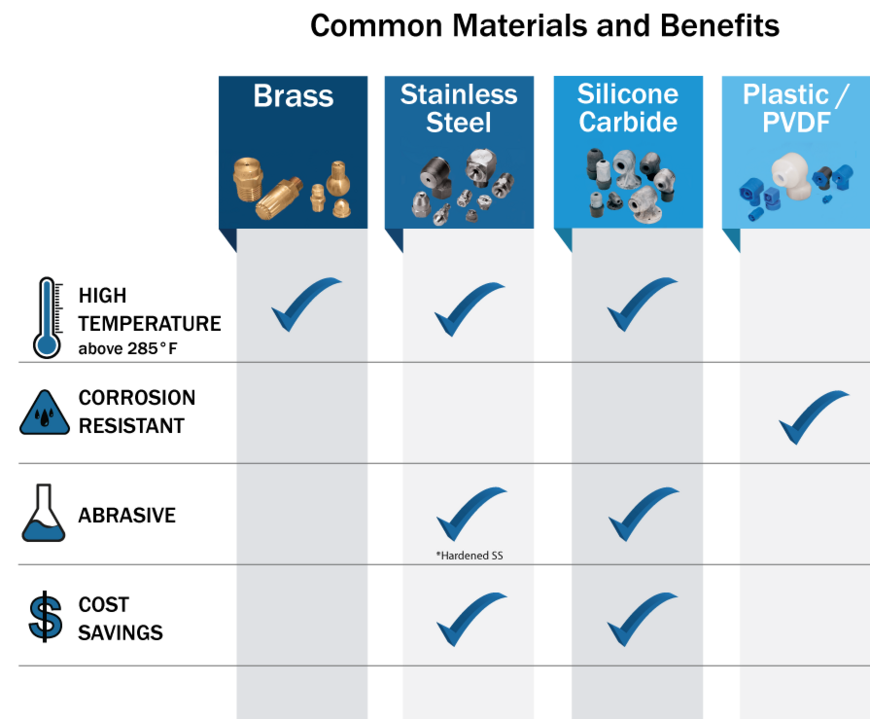

From brass to stainless steel to plastic and any exotic materials, Lechler offers an extensive assortment of spray nozzle materials. With a variety of materials to choose from, how do you know which one is right for your application? To help, we have broken down the various factors which should be considered when selecting the appropriate spray nozzle material.

| Temperature - Each type of material will begin to soften or melt once the temperature starts to rise. If your application requires a material that can withstand high temperatures, we recommend brass, stainless steel or ceramic. |

| Corrosion Resistant – Overtime corrosion may occur to nozzles due to changing environments and type of media sprayed. Plastic is a material that is very resistant to corrosion but doesn't do well in a high temperature environment. If your application does require a material that is resistant to corrosion and can withstand high temperatures, we recommend Hastelloy. |

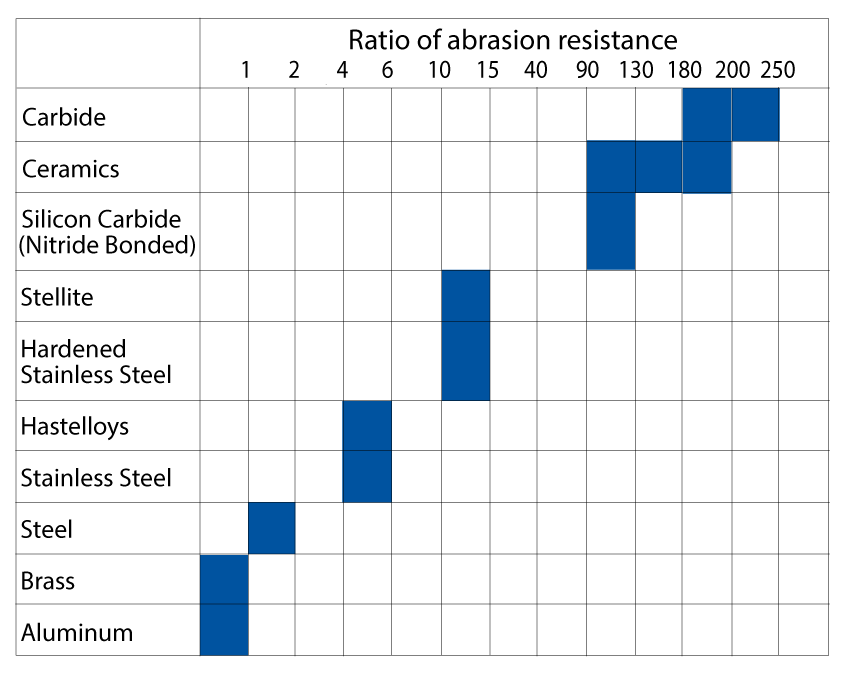

| Abrasive – Nozzles required to spray chemicals such as acids, alcohol or oxides should be made from a strong enough material to hold up to these harsh environments. The chart below shows the ratio of abrasion resistance between the different materials.

|

| Cost Savings– Nozzles made from hard or exotic materials may cost more initially, but in the end they pay for themselves because of their long lasting properties. These nozzles may be more corrosion resistant or abrasive, so they won't need to be replaced as often saving you time and money. |

Consider switching your nozzle material if...

If your nozzle is exposed to extreme temperatures, harsh environments, or is being sprayed with corrosive liquids, consider switching to another nozzle material. Spray nozzles made of harder materials with a higher abrasion resistance ratio, such as tungsten carbide; tend to have a longer life. Other nozzle materials, such as PTFE or PVDF, will work better for applications with corrosive chemicals being sprayed and can extend the nozzle life.