Tank and equipment cleaning

Cleaning nozzles for every container and tank size

Companies all over the world in a wide range of industries rely on Lechler tank and equipment cleaning nozzles for thorough cleaning of all kinds of tank sizes, machines and equipment. The Lechler tank and equipment cleaning nozzle range features innovative drive concepts, state-of-the-art nozzle design as well as a large choice of sizes and materials. The scope of our portfolio is unique to the market and offers the perfect solution for every application.

Lechler nozzles for tank and equipment cleaning

| For every application |

| Cleaning in Place (CIP) Many of Lechler‘s precision nozzles for tank and equipment cleaning are CIP-capable and can remain in the installation during the production process. |

| Hygienic equipment cleaning |

| The right nozzle for every tank Our extensive product range includes the right nozzle size for every application – from a small test tube to a large fermentation tank for bioethanol production. |

Your benefits:

- None of the risks, restrictions and costs related to manual tank cleaning

- Modern nozzle technology reduces cuts cleaning fluid consumption and reduces downtimes

- The cleaning process is trouble-free, repeatable and verifiable

What you should keep in mind when planning

The fundamentals of cleaning technology

Cost reduction by efficient cleaning processes

The fundamentals of cleaning technologyNozzle types and operating principles

Static, free-spinning, controlled rotation gear-controlled?

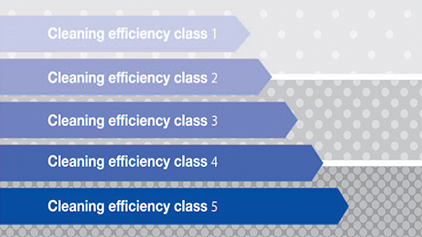

Designs and operating principlesCleaning efficiency classes

Five cleaning efficiency classes for easier nozzle selection

Cleaning efficiency classesCommon Applications for Tank Cleaning Nozzles

Tank cleaning nozzles come in a myriad sizes and design styles to accommodate every size tank, from test tubes during R&D chemical testing to large bioethanol formation tanks for the petrochemical industry. The spray nozzle design includes static heads that do not rotate that are often used for rinsing tanks of all sizes, and rotating heads.

Rotating heads can be free spinning as the fluid drives the rotational force, a rotating head that has an internal gear and turbine wheel, and gear-controlled that rotates by two axes. Here are some tank and equipment cleaning applications that take advantage of this spray nozzle technology.

Food and Beverage

Food and beverage industries require tanks to be clean and sanitized to prevent contamination of products and the possible spread of bacteria that can impact human health. Some common applications include commercial ovens, freezers, brew kettles, and beer tanks.

Petrochemical

Oil and gas refineries rely on effective tank cleaning to remove chemicals completely while keeping workers safe. Many of these chemicals can be reactive and toxic, as the spray nozzles lower the risks of human contact while conserving water resources. Some applications for tank and equipment spray nozzles are reactors, underground storage tanks, above ground storage tanks, and process vessels.

Tank Cleaning for Small Industrial & Sanitary Tanks

Static and rotating spray nozzles that handle light to medium soil are perfect options for small industrial tanks. The low and slim profile can fit into smaller tank openings while still ensuring effective spray coverage. Spray nozzles can fit into opening diameters ranging from 0.84" to 2.72" and operating pressure of 30-40 psi. The free rotating spray nozzles can handle light soiling and rinsing applications most often found in food, beverage, chemical, and pharmaceutical industries for tank sizes of up to 11 feet.

Tank Cleaning for Mid-Sized Industrial & Sanitary Tanks

Mid-sized tanks can go through light to medium soiling as they require spray nozzles that can force the cleaning solutions and rinse water out of reach every crevice and corner of the tank. Static and free spinning nozzles have special geometries that can handle flow rates ranging from 3 gpm to 303 gpm. They are suitable for pressures of 30-40 psi and can accommodate tank openings from 0.87" to 5.75" and tank sizes of up to 18 feet.

Tank Cleaning for Large Size Industrial & Sanitary Tanks

Large industrial and sanitary tanks experience moderate to heavy soiling. Tank and cleaning nozzles use the controlled rotation design that can handle operating pressures of 40 psi to 75 psi and flow rates of 6 gpm to 79 gpm. These nozzles can accommodate tank sizes of 32" in diameter. The flat spray nozzles ensure an effective coating of all surfaces while providing uniform droplet sizes that minimize waste.

For more information about Lechler spray nozzles for tank and equipment cleaning applications, contact us today.