Nozzle maintenance should be a regular part of your production process if you want to keep your lines running efficiently. This is why the engineers at Lechler developed a Five Step Process for extending nozzle life. Learn about the factors that can cause poor nozzle performance and what signs to look for when your nozzle is not spraying properly. By following the Five Step Process, you can learn how to prevent significant quality problems and profit loss

Our team of engineering experts have developed a 5 Step Process for maintaining nozzle performance. By following these 5 simple steps, you can extend the life of your nozzle and prevent costly quality issues.

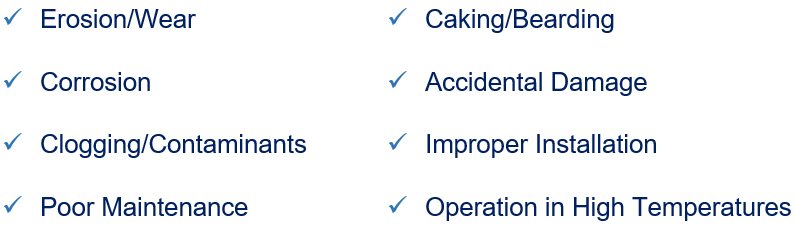

Environment can affect the material of a nozzle, which can cause erosion and wear. Selecting the proper material is critical to ensure longer nozzle life. Nozzle materials such as PTFE or PVDF work better than metals if corrosive chemicals are being sprayed.

Proper filtration can eliminate unwanted particulates, which can result in clogging and restricting nozzle flow. For this reason, a line strainer, or built in nozzle strainer is recommended with a screen mesh size that will prevent particulates from entering the nozzle.

Nozzle cleaning should be done on a regular basis but with proper care. Only use plastic bristle brushes, wooden or plastic probes when cleaning nozzles. Avoid using wire brushes and metal knives because these can damage the nozzle orifice shape, resulting in poor spray performance. If the nozzle is clogged, soak the nozzle in a non-corrosive cleaning chemical, which will soften and eventually dissolve the particulate matter.

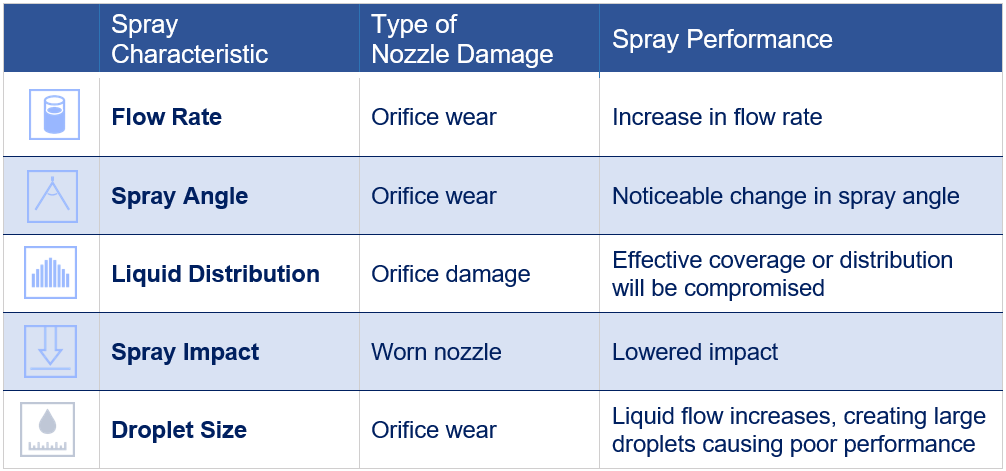

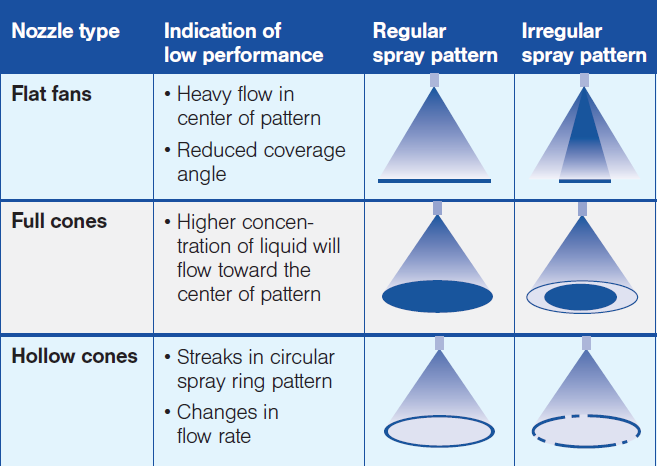

Nozzles should be inspected on a regular basis and be a part of your standard operating procedure. The most common routine nozzle maintenance procedures involve:

Lechler also provides wear test programs for a select group of nozzles. Our laboratories are equipped with spray testing equipment for this task. Nozzles are sent directly to Lechler for inspection and testing. Our team of experts will check both spray angle and flow rate to make sure the nozzles are within operating tolerances. The final pass/fail results are recorded on the Wear Test Report and provided to the customer.

Contact us today for a Free Copy of our Spray Nozzle Maintenance Guide.

Our Spray Nozzle Maintenance Guide is a convenient fold out brochure including the Five Steps you need to know for extending nozzle life. The brochure is made from special grease-proof paper, which resists soiling so that it can be kept in the maintenance area.