Axial Vs. Tangential Nozzles

Lechler categorizes its full cone vs hollow cone nozzles into two different groups; axial and tangential. Both are used in a variety of applications but what is the difference?

Lets explore each one starting with the Full Cone nozzle group...

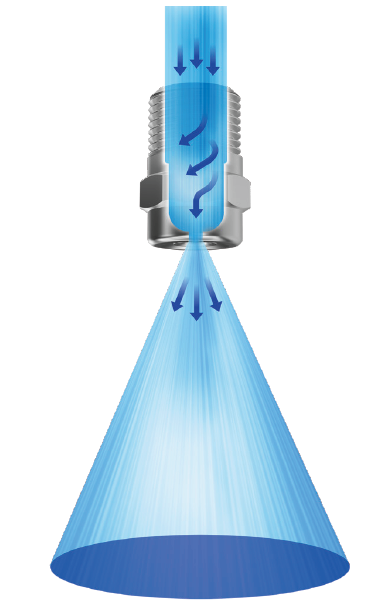

Axial Full Cone

| The most common full cone is axial, this design creates an even spray over a circular area. Spray formation, liquid distribution, and shaping of droplets are generated by a revolving motion of the liquid, which is achieved with the aid of swirl inserts inside the free cross-section of the nozzle. The axial full cone is available with low and high flow rates in a wide range of spray angles and is perfect for the following applications:

|

Axial full cone nozzle with higher flow rate

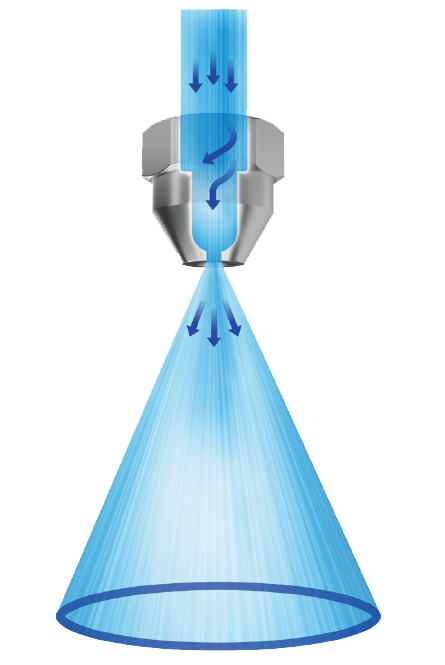

Tangential Full Cone

| Unlike axial, tangential full cone nozzles are not designed with a swirl insert and are therefore less prone to clogging. The full cone spray pattern is produced by grooves milled into the bottom of the nozzle, which provide a defined deviation of the liquid flow to the mixing chamber’s center. This chamber creates a uniform area distribution of the atomized liquid so that when it exits the orifice the spray is evenly dispersed. Tangential full cone nozzles are designed for the following applications:

|

View all Tangential Full Cone Nozzles

Axial Hollow Cone

| Axial Hollow cone nozzles are designed with spiral grooves in the swirl insert which create a liquid whirlwind effect. This whirlwind effect generates small uniform droplets that can be absorbed faster, cool quicker and moisturize better for applications such as:

|

Axial Flow Hollow Cone Nozzle

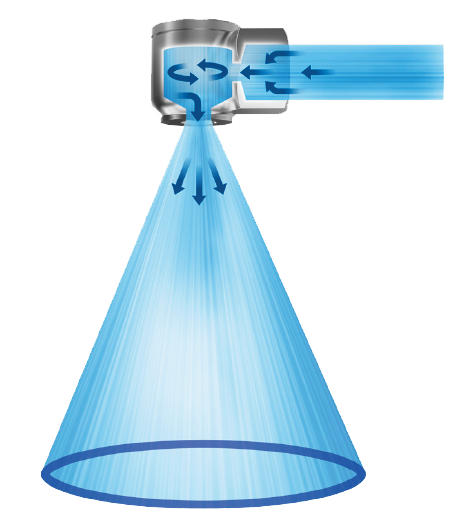

Tangential Hollow Cone

| The tangential hollow cone is designed with an off center inlet combined with a 90° turn. These internal features create a whirling rotation of liquid within the nozzle chamber resulting in smaller droplets and even distribution. Tangential hollow cone nozzles do not include a swirl insert making them less prone to clogging. Typical applications for tangential hollow cone nozzles include:

|