Fluid Dynamics

The intelligent way to optimally use nozzles

When considering flows, turbulence and highly complex spray processes, nobody knows the possibilities better than we do. Just as no one knows your requirements better than you. Together we can find out how to use all your potential.

We do not promise perfection - we expect it.

For well over a century, we have been developing and producing nozzles and nozzle systems for many different applications. This resulted in a unique understanding of spray and atomization processes in a variety of applications over a wide range of pressures, temperatures and atmospheres. We are constantly working to improve the precision and efficiency and open up new application areas.

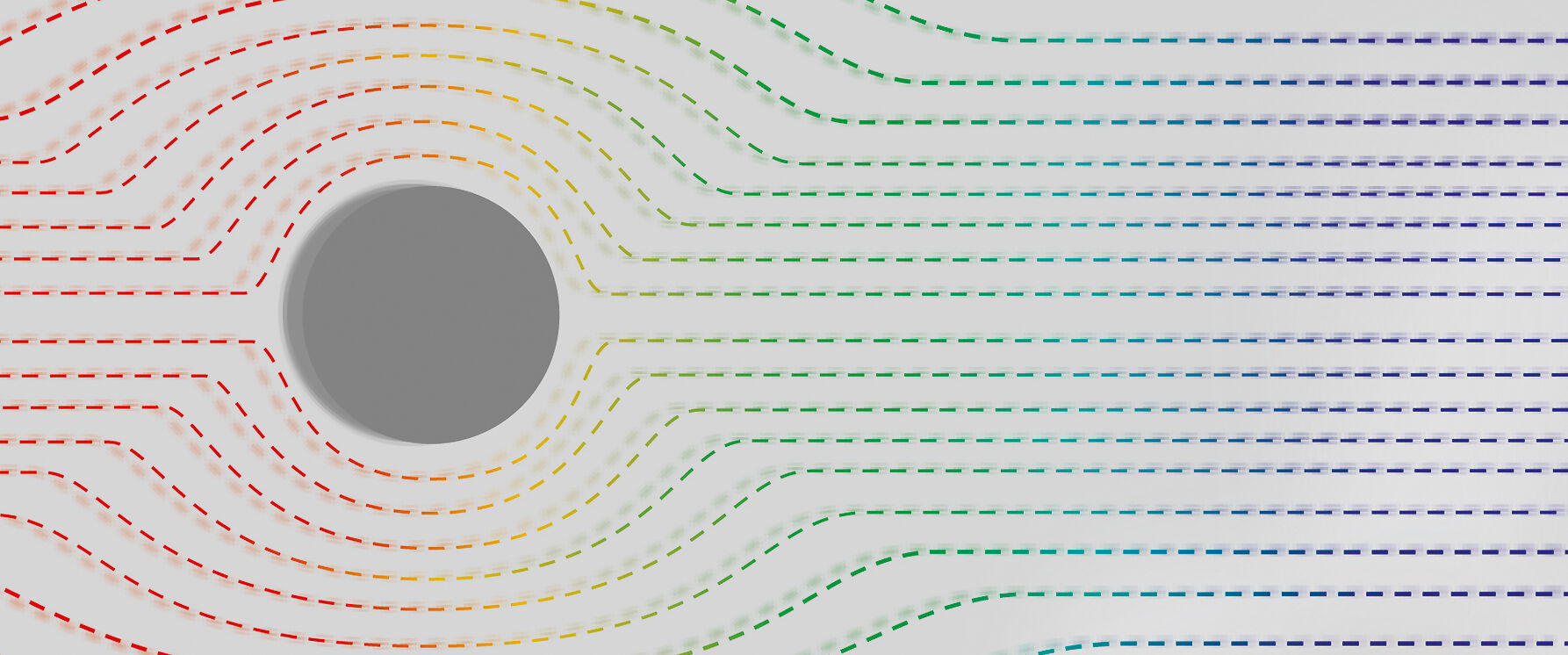

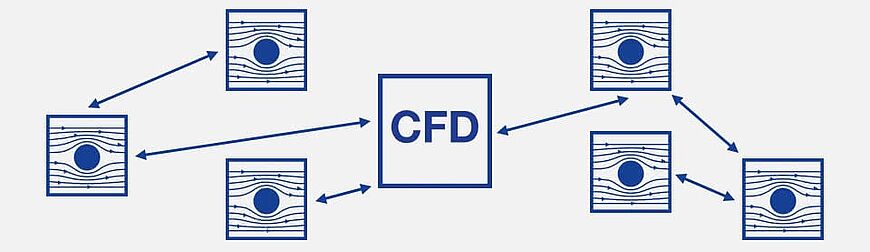

For simple calculations such as a straight piece of pipe, the flow state is still relatively easy to calculate using paper, pencil and calculator. If there is just a slight curve, then this is not so easy. Here, Computational Fluid Dynamics (CFD) is required.

We have used our expertise from many decades of nozzle development for these simulations. Conversely, CFD was initially just an internal tool that aided us in developing a desired nozzle faster and more accurately. Our high-performance clusters with a computing power of around 8,500 GFlops allows us to offer our knowledge as a service today. We simulate nozzle applications and processes individually for your environment and your requirements. This ensures that everything runs optimally in the real world.

Flow simulation as a service

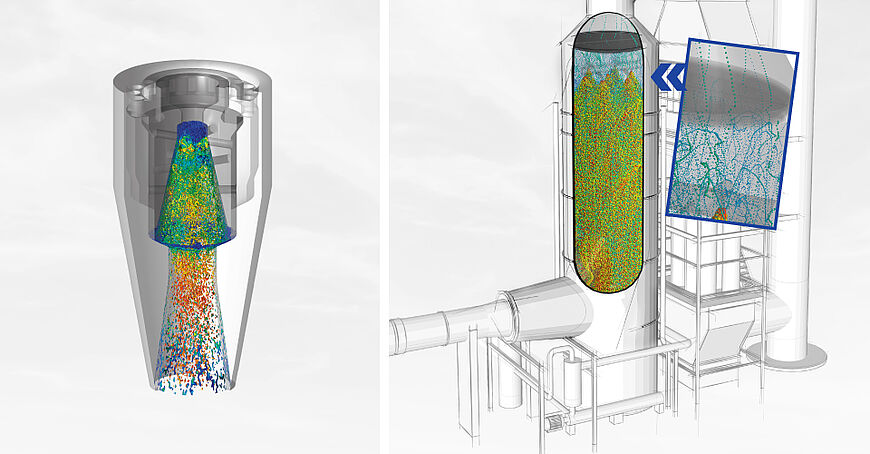

Simulation Laval nozzle (left), scrubbing tower for the treatment of process gases (right)

Simulation Laval nozzle (left), scrubbing tower for the treatment of process gases (right)Our offer

- Calculation of the flow field including the pressure losses with one or more flowing media in piping and fittings.

- Spray coverage including heat and mass exchange with the surrounding gases under almost all conceivable environmental conditions.

- Calculation of internal nozzle flows and prediction of the spray pattern, the water distribution, the spray characteristics and droplet sizes near the nozzle.

Our expertise

- Experience and expertise in the field of spray processes and nozzle development.

- Over a decade of experience using CFD analysis for spray generation, coverage and application.

- High performance computer for complex CAE applications.

- Professional spray laboratories with specialized measurement equipment for practical tests and validations.

Your benefits

- Maximum efficiency

- when using expensive consumables

- in the geometric measurement of the entire spray process

- Targeted optimization

- of the choice of nozzles

- of the nozzle operating point (considering the pumps, compressor and blowers)

- of the liquid distribution

- of the droplet sizes

- of the inflow and outflow of your process gases to the spraying process.

Fluid Dynamics in action - customer-specific process optimization

Even with spray processes that have been running smoothly for years there is usually a considerable potential for optimization. Using our process simulations we can find these without interfering with the ongoing production. In this way, different settings can be tested, checking their impact on total yield. Here we rely on a clearly defined workflow:

- Project definition

- Inventory analysis using CFD to define the initial situation and identify the potential for optimization

- Optimization using CFD for virtual review and evaluation of individual measures

- Implementation

Your benefits

- Identification of optimization potentials

- Virtual evaluation of individual measures

- Risk-free, virtual trials

- Time-saving

- Identification of potential savings

- Clear amortization analysis

Use our engineering experience to your advantage. We are pleased to assist you with our experience acquired over the decades with your process optimization. Contact us right now. We would be happy to define the work package together with you and submit a concrete offer.

Fluid dynamics process simulations

Contact-free evaporation

Optimization of evaporative coolers

Fluid dynamics process simulations - Project: Contact-free evaporationPerfectly calculated

Washing tower for the treatment of process gases

Fluid dynamics process simulations for denitrificationHighly corrosive

Sulfuric acid injection for the purification and cooling of process gases with sulphur trioxide

Fluid dynamics process sulfuric acid injection