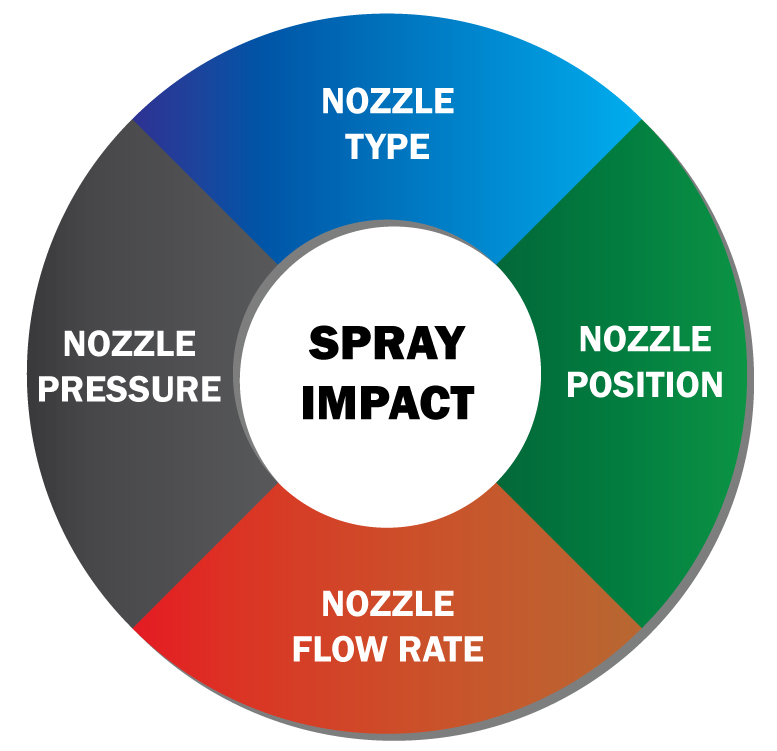

One of many important characteristics of nozzle performance is spray impact. Impact is defined as the impingement (force) of a spray upon its target (surface area). Many factors can influence spray impact and we will identify each one and discuss how nozzle performance can also be affected.

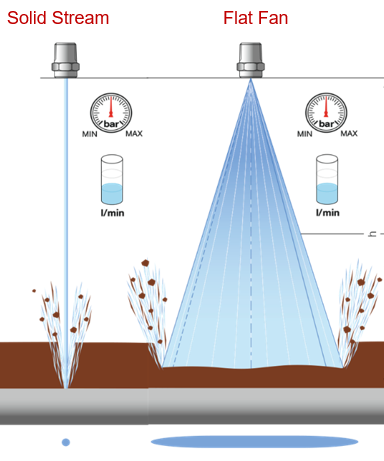

The type of nozzle being sprayed can influence impact. In the image below, a solid stream nozzle and flat fan nozzle spray from the same distance at the same pressure and flow rate. However, the solid stream nozzle provides more impact than the flat fan nozzle because the solid stream is concentrating more flow per area than the flat fan nozzle. The flat fan nozzle has a wider spray angle and the spray will provide you with more coverage but will concentrate more flow over a larger concentrated area.

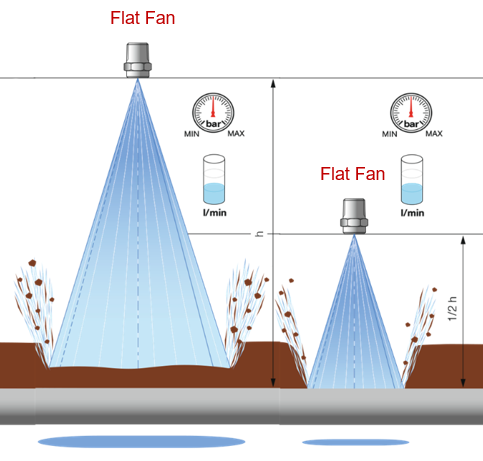

Nozzle position can affect spray impact. In the image below, the flat fan nozzles have the same pressure and flow rate but one flat fan nozzle is placed at a shorter distance. At a shorter distance, the spray impact is greater because you are concentrating the same amount of flow in a smaller given surface area.

Nozzle position can affect spray impact. In the image below, the flat fan nozzles have the same pressure and flow rate but one flat fan nozzle is placed at a shorter distance. At a shorter distance, the spray impact is greater because you are concentrating the same amount of flow in a smaller given surface area.

For design considerations, bringing the nozzle closer to the target will give you more impact but your overall coverage will be compromised.

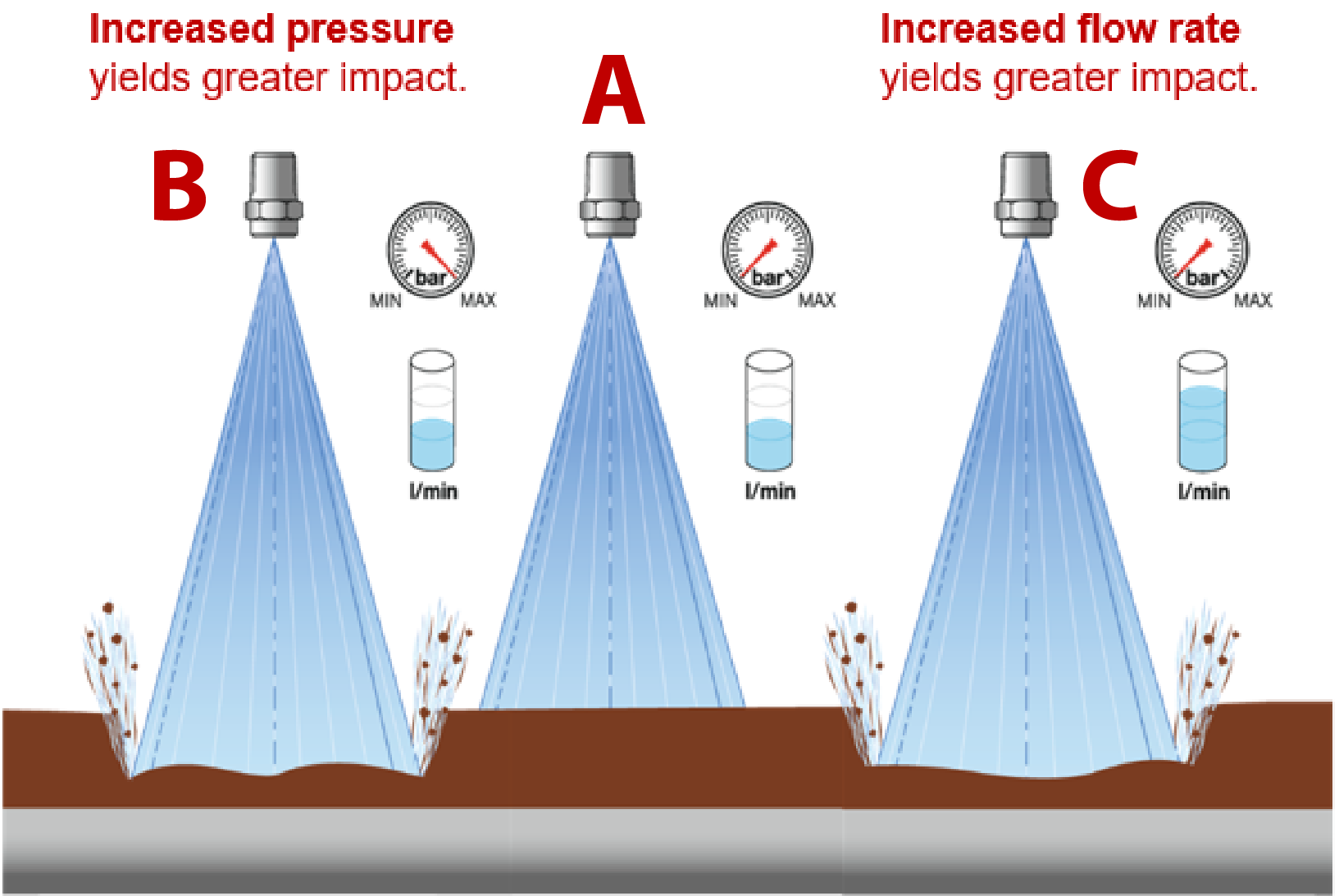

Two additional factors that will increase impact are flow rate and pressure. As shown in the image below, Nozzle A and B are placed at the same distance and the flow rate is the same. However, the pressure for Nozzle B is greater than Nozzle A and results in higher impact at the target area.

Two additional factors that will increase impact are flow rate and pressure. As shown in the image below, Nozzle A and B are placed at the same distance and the flow rate is the same. However, the pressure for Nozzle B is greater than Nozzle A and results in higher impact at the target area.

Now consider, Nozzle A and C in the image below, which are placed at the same distance and have the same pressure. However, the flow rate in this scenario for nozzle C is greater and results in higher impact at the target area. Increasing flow rate and/or pressure at the same distance will provide greater impact on the target area.

In general, nozzles are designed and tested for optimized performance. At Lechler, our engineers can assist you in selecting the best nozzle for your spray application.