Air Nozzles

Air nozzles are used for dispersing air or steam in a concentrated and straight fan. Generally, air nozzles have a flat fan or solid stream spray pattern. When using conventional air nozzles, air is blown through a single hole. Often a loud, ear-splitting and hissing noise is produced. To avoid this unpleasant noise, Lechler has designed special multi-channel air nozzles. Sound level and air consumption of these nozzles are very low.

Types of Air Nozzles

Flat jet nozzles for air

Flat jet nozzles for air are used for dispersing air or other gases in a concentrated and straight fan.

Round jet nozzles for air

Round jet nozzles for air are used for dispersing air or other gases in a concentrated and straight fan.

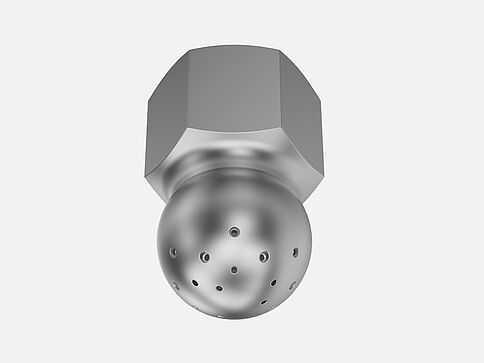

Cluster nozzle for air or saturated steam

Multi solid stream nozzles deliver gases and other media through individual holes.

Detailed Information on Air Nozzles

Efficiency can be so quiet

Compressed air nozzles are used for the targeted application of air or saturated steam. These are usually flat fan or solid stream nozzles. When using conventional air nozzles, in which the air is simply blown through a hole, loud hissing noises often occur. To avoid these unpleasant noises, Lechler has developed special multi-channel compressed air nozzles which are extremely quiet and economical in air consumption

Air nozzles have a spray angle, even if this seems implausible at first glance. When the air escapes, the ambient air is entrained, resulting in a widening of the spray. The spray angle is approx. 20°.

Your benefits by using of Lechler air nozzles

- Reduced noise level

- Low operating air pressure with the same blowing force

- Lower air consumption

- Improved blowing efficiency over larger distances

- Lower operating costs

Three advantages for you

Cost efficiency

Lechler nozzles make it possible to reduce compressed air consumption by up to 45 %, in comparison with open pipes. Increasing energy costs and the growing range of applications for compressed air become more evident for the impressive potential savings possible in this area. This is a competitive benefit that has a direct positive impact for your business.

Employee safety

The unique design of our nozzles allows the noise level to be verifiably reduced by up to 25 % in comparison with conventional solutions. This also reduces noise-related stress for your employees. Since concentration falls as a result of increased stress, the use of low-noise nozzles has a positive effect on production quality.

Service offering

A perfect solution must be optimally tailored to the exact requirements. We will therefore gladly advise you in person about the use of compressed air nozzles and introduce you to new possibilities. Contact us and let us define the best possible solution together for improved quality and optimized process reliability.

Lechler air nozzles have proven themselves in many areas of industry

Application: Cleaning and blowing off

Air nozzles are very frequently used for blowing off swarf.

Your advantage:

- Efficient removal of swarf

- Reduction in noise level (e.g. with Lechler Whisperblast nozzle)

- Fixed installation or connection to air gun possible

Application: Cooling

In addition to cooling with water, surfaces can also be cooled by air and other gases.

Your advantage:

- Surface cooling without water

- Uniform cooling effect

- Reduced noise level due to multi-channel air nozzles

Application: Drying

In the beverage industry, liquid droplets may occur on the bottles during the filling process.

Your advantage:

- Removal of unwanted liquid droplets (e.g. in bottle filling processes)

- Improved printing

- Higher productivity thanks to faster drying times

Application: Selecting and Sorting

By operation with short pulses, air nozzles can select and sort objects.

Your advantage:

- Removal and sorting of objects on conveyor belts

- Precise control by short, powerful air pulses

- No contact with objects, hygienic operation

Application: Ionizing

The semiconductor industry uses air nozzles to supply ionized air to the manufacturing process.

Your advantage:

- Ionized air supplied to the manufacturing process

- No buildup of static electricity

- Quality assurance in the semiconductor industry

Application: Creating an Air Curtain

If air nozzles are arranged closely together, it is possible to create a closed air curtain.

Your Lechler advantages:

- Closed air curtain created by overlapping air jet zones

- Dust and fluid barrier that is gentle on the product material

- Quality assurance in dirt-sensitive processes

Measurably more advantages with Lechler air nozzles

Modern air nozzle technology stands for greater efficiency and less noise. Our comprehensive knowledge of nozzle technology combined with a deep understanding of application-specific requirements form the basis for products of extraordinary performance and reliability. Lechler air nozzles therefore offer

- larger measurable spray pattern,

- higher measurable blowing force,

- less measurable noise and

- a lower measurable air consumption.

Spray pattern measurement

The compact design and unique form of our air nozzles allow for extremely high speeds in the near range as well as larger throw distances.

Blowing force

Measurements show that Lechler multi-channel nozzles achieve a high blowing force even at large distances.

Noise level

Standard-based testing of our air nozzles requires that Lechler nozzles are classified by the German Employers‘ Liability Insurance Associations as a valuable aid to reduce noise in production environments.

Air consumption

Nozzles from Lechler are designed so that they need less compressed air than conventional nozzles, without the need to compromise on performance.