What Is An Eductor Nozzle

Unlock the secrets of the eductor nozzle: Explore its functions, applications, and how it revolutionizes fluid dynamics in industries.

What is Spray Atomization?

Explore the role of atomized spray nozzles in enhancing efficiency and productivity in manufacturing, pharmaceutical, and marine operations.

Spray Nozzles for Evaporative Cooling & Disposal

Evaporative cooling nozzles enhance water cooling, ensure efficient evaporation, reduce contaminants, and aid disposal for various industries.

Common Spray Nozzle Problems & Solutions

Understanding common spray nozzle problems & solutions can help you develop a proper maintenance program to prevent or minimize issues with your equiptment. Click here to learn more about common spray nozzle problems and their solutions.

Cleaning Solutions for Glass-Lined Reactor Equipment

Glass lined reactor jacket cleaning can be difficult. Learn helpful solutions with Lechler today!

Conveyor Belt Cleaning for Bakery Processing

Conveyor belt cleaning methods are based on various factors to determine the types of cleaning that needs to be performed as well as how oven cleaning takes place.

Air Atomizing Spray Pattern

Air atomization is when air or gas is added to liquid to create a fine mist. This mixing of the air and liquid may be done within the nozzle itself or directly outside the nozzle opening.

Food Processing Equipment Sanitation: Why is it Important?

Food processing sanitation equipment has become a vital and necessary operation through the food industry. In 2021 alone, there were 47 product recalls that resulted in 15,501,273 pounds of food being sent back to the manufacturers, according to the USDA Food Safety and Inspection Service.

Manual vs Automatic Tank Cleaning

Automatic tank cleaning offers a way to clean tanks without needing staff. This method increases the health and safety of workers who don't have to enter tight spots to perform cleanings.

Descaling Steel - Metallurgical Process

While descaling steel can consist of many different processes, there are typically 4 descaling categories. Read on to learn more today!

Cleaning Mist Nozzles: How to Clean Mister Nozzles

Many industries rely on misting nozzles to provide cooling to certain processes. In industrial metal manufacturing, misting is used to cool the metal's strand in a controllable way to assist in maintaining the desirable properties in the cast metal.

Water Atomization: Water Atomizing Process and Best Nozzles

Metal manufacturers provide a range of base metals and alloys for customers who use these materials to create metal products. While pure metals may be used, often the metal becomes processed to remove impurities, place in additives to create alloys and superalloys, and to make the metal into specific shapes and sizes.

IBC & Tote Cleaning

Our high quality spray nozzles consistently clean and rinse every surface of the tote in an even manner. Read on to learn more about IBC and tote cleaning!

What is Spray Drying in the Food Industry?

The food products found in grocery stores go through many processes to ensure that each product maintains the high quality standards necessary for consumption.

Dust Suppression: What is Dust Suppression?

When performing indoor or outdoor application, many commercial and industrial settings deal with voluminous amounts of dust. The dust may come from the outdoor environment, exterior air sources pumped into interior spaces, workstation processes, or from manufactured products. Industries that may deal with dust include food processing, chemical, construction, steel manufacturing, recycling plants, dry bulk goods warehousing, mining, agriculture, and paper/wood processing.

Water Conservation: A Key To Environmental

In industrial operations, manufacturers rely on water to complete certain functions. Factories use water to cool equipment, process products, wash away contaminates, and dilute chemical concentrations. Water may also be used to transport materials, as a heat transfer process, and be placed into products to keep them liquid or semi-fluid.

Coating Nozzle Overview – Applications & Insights

A coating nozzle allows for the application of sprays onto objects in an efficient and consistent manner. The nozzles also ensure only the right amount of spray is applied, conserving products, and lowering the amount of waste.

Work Roll Cooling for Steel and Aluminum Producers

Steel and aluminum producers are facing challenges in producing the next generation of sheet products required by today’s consumers across many industries. To achieve these high quality products, optimized & effective “Work Roll Cooling” in both hot and cold rolling is critical.

What is Ware Washing & What’s Involved?

In a restaurant, hospitality establishment, cafeteria, and other commercial setting where food is served, workers need to have a study supply of plates, glasses, utensils, pots, and other cookware. Washing these items one at a time when serving lots of people creates an inefficient use of time. Learn how to streamline this process here!

The Best Pretreatment Options to Save Money

The surface of the metal must be prepped to ensure that the powder successfully adheres to the surface. In addition, pretreatment is another method when prepping for powder coating processes. Pretreatment involves changing the metal's surface chemistry to enhance the metals properties and to ensure the powder coating bonds to the metal.

How to Optimize Your Circuit Board Cleaning Equipment

Manufacturers develop printed circuit boards (PCBs) to perform these simple and complex functions. An important issue experienced by manufacturers involves keeping circuit boards clean during production. Read on to learn how to do it efficiently and effectively!

Industrial & Technical Cleaning: Everything to Know

Manufacturing operations rely on a range of equipment to make products based on their particular industries. See how to keep it clean here!

The Difference Between Hot Rolling & Cold Rolling

Interested in learning more about the production processed involved in the creation of steel products? Read on to learn about the unique differences between hot and cold rolling from the experts at Lechler.

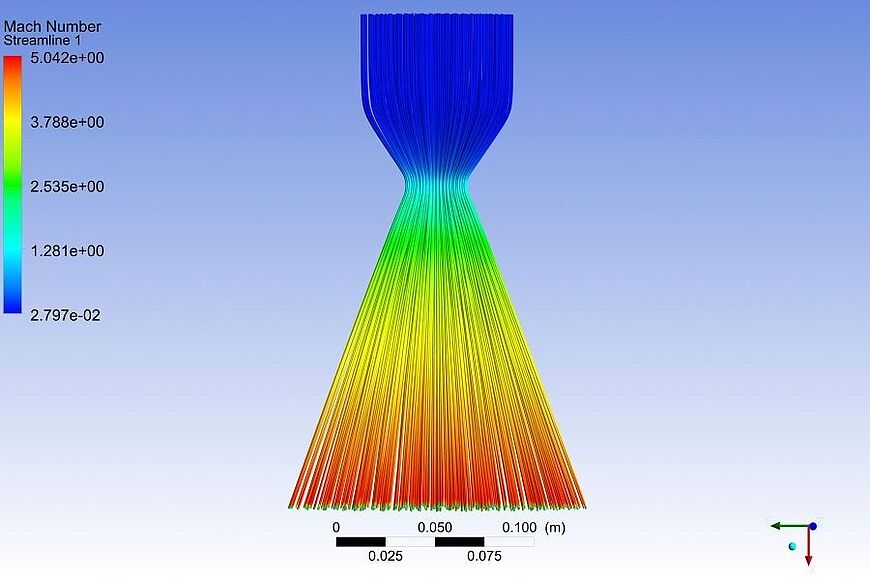

Computational Fluid Dynamics: Engineering an Efficient Spray System

Computational fluid dynamics (CFD) have radically changed the way engineers are able to make projections from fluid flow equations.

Custom Nozzle Fabrication

What makes a spray system? A compilation of headers, nozzles, lances, and quills. There are many factors to be considered with custom nozzle fabrication.

Produce Spray Nozzles: Vegetable Washing Machine

We want to take a few moments to focus on the spray nozzles used in food and beverage production. More specifically, we will discuss the many nozzles involved in vegetable washing and preparing produce and food for packing, shipping, and ultimately the consumer.

Lechler Spray Ball Manufacturers: Trusted Globally

Because the industries we serve are constantly changing, our spray ball technologies are always changing and evolving with new capabilities.

Barrel and Tank Cleaning Systems

Understand the benefits of barrel and tank cleaning systems, including what they are, how they work, and the benefits for your business.

Differences Between Steel and Plastic Nozzles

Selecting the right spray nozzle for your application is not always a simple task. From nozzle size and type to material, a dozen variations exist, purposefully designed for distinct functions.

Disinfection vs Sterilization: The Best Nozzles for Both

While both refer to decontamination, disinfection and sterilization are distinct – and understanding the differences is critical in industrial spaces.

The Most Effective Chemical Tank Cleaning Process

Cleanliness is particularly prevalent when considering tanks used in production. Explore the most effective chemical tank cleaning process to produce trusted, high-quality products every time.

Food & Beverage: Clean In Place (CIP) Tank Cleaning

Equipment cleanliness goes hand-in-hand with the quality of your product. Follow along as we explore effective and efficient tank cleaning methods for the beverage industry.

Fire Protection Spray Nozzles

Explore a few of the most important considerations to take into account when choosing your own fire protection system that will help you select the best approach for your application.

Reducing Temperature for Optimized Ball Mill Performance

Excessive heating generated by ball mill usage can spell disaster for your products. Learn how to keep cool under pressure with Lechler nozzles.

Spray Nozzle Technology – Combining Quality & ROI

Learn how a powerful Spray Nozzle Manufacturing Process can be leveraged to deliver nozzles of the highest quality and increase your Return on Investment.

How to Use 4 Categories of Cleaning Agents for Deeper Cleans

Learn more about the 4 categories of cleaning agents and how you can leverage them to improve the cleanliness of your facility & processes.

Benefits of Humidification Control by Industry

Want to learn more about the benefits humidification control can have in your particular industry? Browse this comprehensive guide. Humidification control nozzles.

Maintaining Product Quality in the Food and Beverage Production Process

From sanitation of equipment and products to appearance, the quality control requirements of our food are some of the most stringent of any industry.

How to Select the Correct Spray Nozzle for Your Specific Application

Lechler has over 25,000 nozzle varieties. Read our blog to learn more about which nozzles are best for your industry and required application.

What Are the Basics of Tank Cleaning?

Discover how to uphold proper cleaning standards for your tank cleaning needs with Lechler nozzles.

How Do I Know When My Spray Nozzle is Worn?

We discuss maintenance designed to extend nozzle life, as well as common symptoms of damage that require further action.

Conventional vs. Multi-Channel Air Nozzles

We discuss the differences between both air nozzles, closing with the advantages of a multi-channel air nozzle for countless applications.

Food & Beverage Industry Equipment Cleaning: Selecting a Safe, Effective Method

We discuss how evaluating your needs, planning for the right cleaning solution, and knowing options will help you to select a safe equipment cleaning method.

The Importance of Disinfection and Hygiene in the Food and Beverage Industry

As consumers are offered a more extensive product range, improved processes are required. Be sure you have the proper tools to maintain hygiene regulations.

Reduced Emissions Through Evaporative Gas Cooling

We explore the importance of evaporative gas cooling, the evolution of cooling systems, and how to apply proper fluid application inside of a downcomer duct.

When Should Food Production Equipment Be Cleaned and Sanitized?

We explore one industry uniquely prone to bacterial buildup, tips to keep your equipment bacteria free, and the best nozzles to keep equipment consistently sanitized.

The Best Rotating Cleaning Nozzles for Penetrating Your Most Difficult Soils

With over 140 years of engineering experience, our cleaning nozzles maintain a reputation of excellence and are designed to penetrate difficult soils every time.

Simple Ways to Reduce Water Consumption

In the content below, we demonstrate how simple reducing water consumption can be – with the proper nozzles. Flow capacity, maintenance, and cleaning processes are each explored in depth.

Water Conservation for Industrial Use

As the cost of operations rises across many industries, conserving water is an excellent way to save money and resources without compromising quality.

The Need for Efficiency: How a Major Fast Food Chain Benefited From a Smoother Process

Workers in the food and beverage industry expect to use easily operable and maintainable equipment, allowing them to perform their own jobs efficiently.

The Use of Flushing Nozzles to Clean a Lauter Tun

Explore the role of the Lauter Tun in the brewery process, cleaning challenges associated with this piece of equipment, and Lechler’s custom solution.

Measurement Technology Center

Lechler has a state-of-the-art laboratory and testing facilities, allowing our engineers to perform rigorous trials and accurately document each spray nozzle’s features and spray forms.

Refurbishment Services

Lechler provides in-house and on-site refurbishment services to prolong the useful life of your nozzle systems and ensure maximum efficiency during use.

Interview with Bob Garstki: Tank Cleaning Considerations to Help Improve Your Process

Aside from nozzle operating principles there is additional criteria that you should take into consideration for your tank cleaning process.

Cleaning Food Processing Equipment: The Process

Increased demand requires greater production and reduced downtimes, leaving little room for error, especially when food safety and quality are critical.

High Pressure Isn't Always Effective

Specific details, such as pressure and impact, are equally important for optimal efficiency, accuracy, and consistency as choosing the right nozzle.

The Proper Guide to Tank Cleaning

In the content below, we explore each facet of tank cleaning in depth. Our goal: to provide a helpful guide to plan a perfect tank cleaning process.

Series 5P5 “PopUp Clean” Nozzles: Eliminating Spray Shadows

We’ll discuss the 5P5 “PopUp Clean” nozzle, an FDA-compliant tool for cutting-edge equipment sanitation, such as eliminating spray shadows.

The Benefits of High-Quality Coating Nozzles

For industries that require viscous product coating, such as food-processing plants, utilizing excellent nozzles is crucial to producing quality products.

Spray Technology for Food Processing

Consistency is important to nearly every area of life. In the food industry, consistency is crucial – especially when food spray coatings are applied.

Experience Cost Savings and Better Performance with Rotating Water Heads

Rotating water heads provide cost savings and better performance, serving your bottom line and streamlining your cleaning process.

The Best Types of Nozzles for Efficiently Cleaning Your Food Processing Tanks

Consumers and producers alike understand how important it is for food processing tanks to be efficiently kept clean and free of bacteria.

How the Right Water Nozzles for Cleaning Can Save Your Company Money

The right water nozzle for cleaning your equipment can save your company precious resources. This helpful guide provides the information you need to know.

How to Effectively Remove Beerstone Buildup with Controlled Rotational Cleaning Devices

With the help of controlled rotational cleaning devices, your tanks will become beerstone buildup free during the cleaning process.

Save Money by Choosing the Right Tank Cleaning Nozzle

Choosing and utilizing the right tank cleaning nozzle for your specific application will save money and important resources.

The Importance of Following Proper Brewery Tank Cleaning Procedures

The importance of following proper brewery tank cleaning procedures can’t be overstated. With the correct nozzle, they will ensure a safely cleaned brewery tank.

Are You Using the Proper Tank Cleaning Device for Your Application?

Searching for tank cleaning solutions results in many cleaning nozzles. With many options, how do you know if you are using the proper tank cleaning device?

What is the Best Way to Dispose of Large Quantities of Wastewater?

Wastewater industry workers know that the disposal of wastewater is no small task. This article explores the best practices for wastewater disposal.