Food and Beverage Industry

Increasing Demands Require Innovative Designs

The food and beverage industry is facing enormous challenges as consumers demand more choices. Along with these demands, planning, production processes and reliability must work perfectly together to reduce costs and ensure quality. Production equipment must also meet the requirements of the new laws and regulations for this industry. Lechler offers nozzles that meet hygienic standards and our innovative designs help automate processes. Learn more.

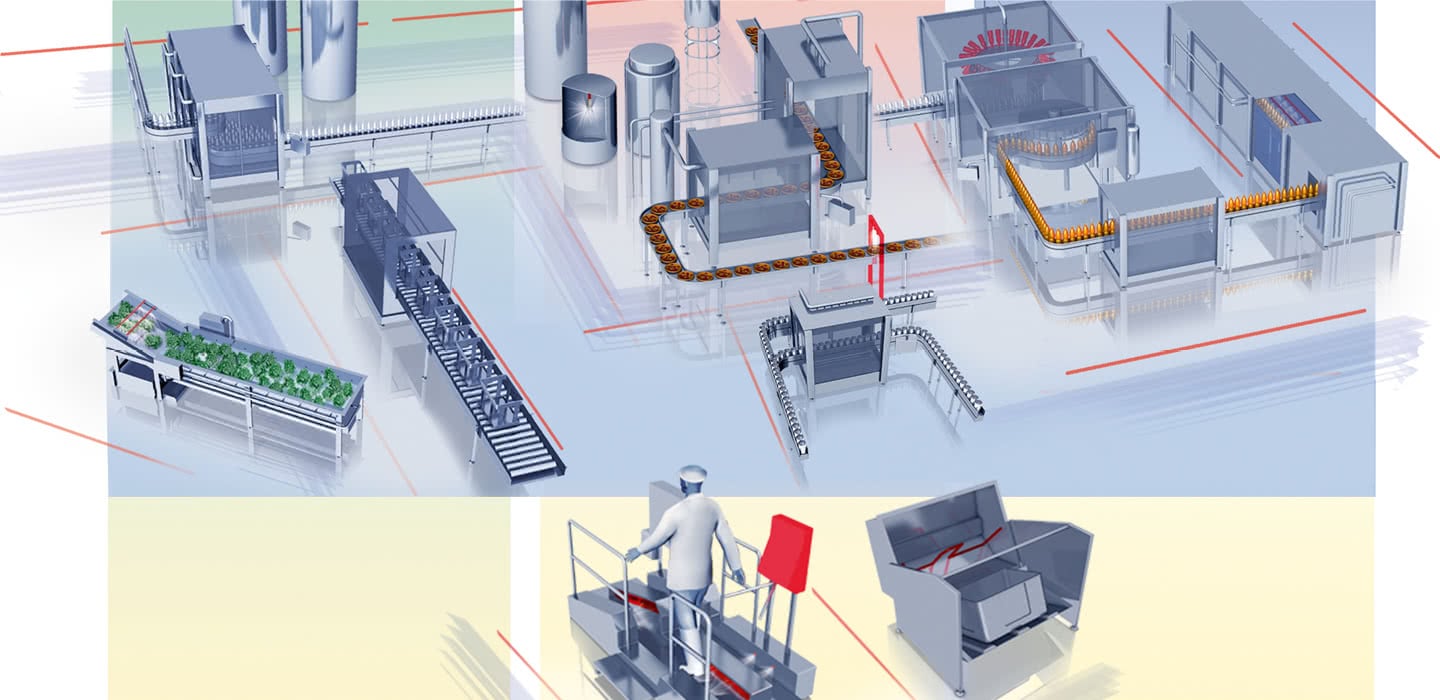

Application ares for Lechler nozzles in the food and beverage industry