Nozzles for Sorting and Packaging

Lechler Nozzles for Sorting and Packing

Sterilization

- Specialized nozzles such as the 136 Series pneumatic atomizing nozzles for disinfecting the interiors of PET bottles

- Fog-like atomization of disinfectants

Filler cleaning

- Reliable, maintenance-free cleaning in compliance with special material and design guidelines (FDA, 3-A, EHEDG, etc.)

- Resistance to a wide range of chemical cleaning agents

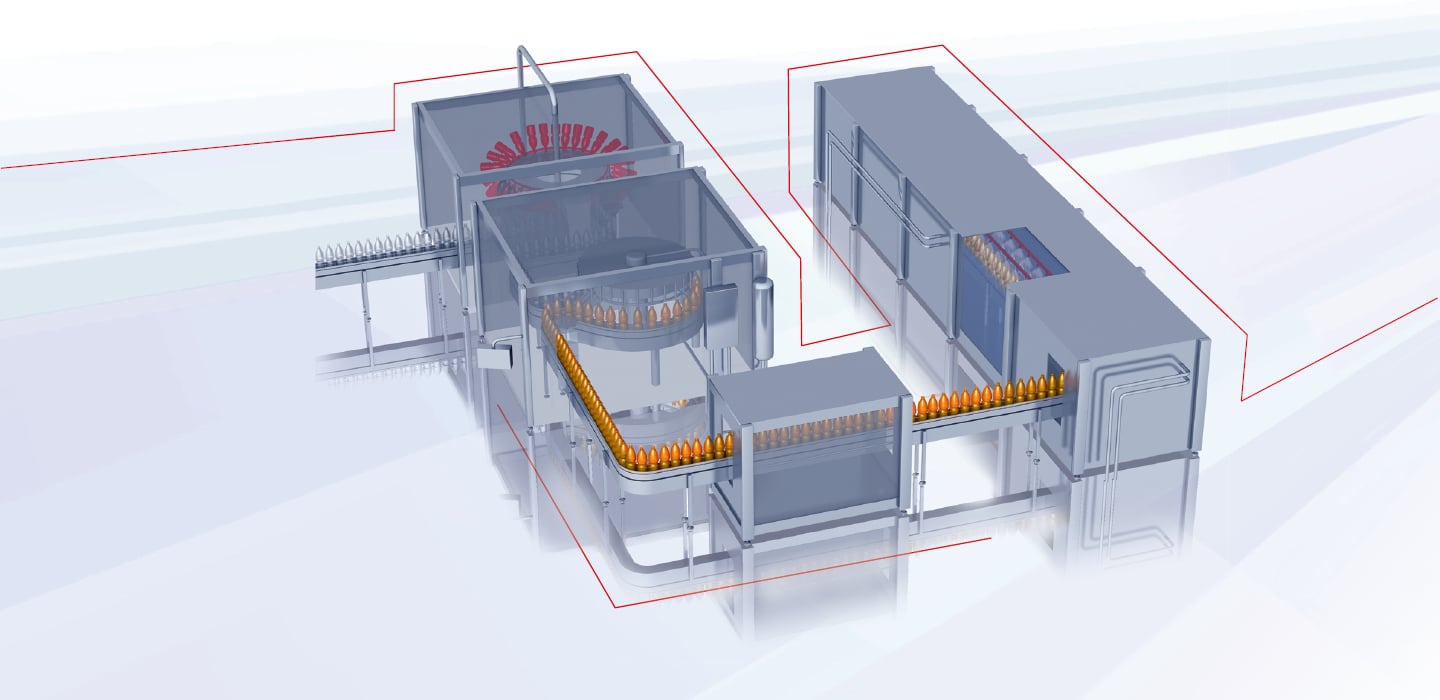

Belt lubrication

- Smooth bottle and crate transport

- Spraying small amounts of lubricant onto conveyor belts

- Nozzles that can process viscous media

Pasteurization

- Targeted heating of products in a pasteurizer for preserving purposes

- Uniform distribution of liquids

- Efficient use of resourcesa

Air nozzles

- Targeted blowing out and blowing off, drying, cleaning, cooking, or heating

- High blowing force

- Low noise emission

Other nozzle applications in the filling and packing field

- Rinsing of bottles

- Anti-Scuffing

- Cooling and moistening bread

- Release agent application

- Drying labels and bottles

- Sorting cans and bottles

- Sorting with air

- PET bottle cooling

Highlighted Products

Nozzles for sterilization

Series 136.1

Applications: Humidification of air, cooling

Nozzles for belt lubrication

Series 652.xxx.8H.03

Applications: Belt lubrication, moistening, spraying of food products, moisturization of rollers, oiling, lubrication of metal sheets.

Pasteurization

Series 422/423 Plastic Version

Applications: Cleaning and washing processes, surface spraying, bottle cleaning, keg cleaning, foam control, degassing, pasteurization.

For additional products, please refer to suggested literature.