Cement/Lime

Making your process better

Cement products have seen consistent upward demand for over three decades. Manufacturers face high production demand while keeping their operational costs low. A major factor in cement manufacturing is the creation of hot gases. These gases are a byproduct from fuel combustion and clinker production as well as being an intermediate product from the calcification and conversion of calcium carbonate, which is the main ingredient of cement. Lechler's spray nozzles for the cement industry offers innovative and reliable solutions for gas cooling and other operations as manufacturers increase their production while reducing gas emissions.

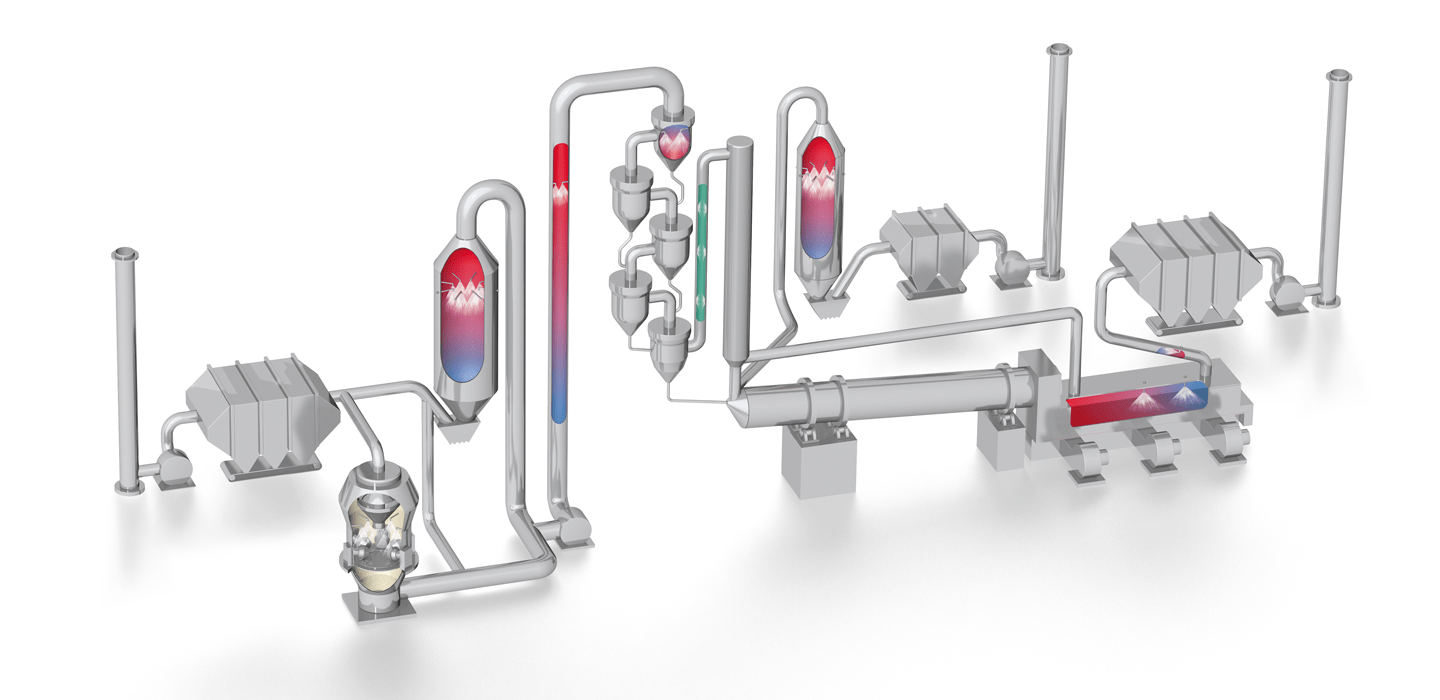

Lechler applications in the cement industry at a glance

Nozzle Lances and Systems for the Cement Industry

Spray nozzle lances and systems are used throughout gas manufacturing processes to help lower the temperatures of emitted gas flows. These nozzles are designed to provide an even distribution of water droplets to create an evaporative cooling process that pulls the heat from the gas. By having efficient nozzles and water systems, cement plants can see a reduction in operation costs by reducing the wear and tear on equipment. You also experience less material and dust buildup on fan equipment to reduce costly repairs and replacement.

Spray nozzles for the cement industry also help manufacturers create better quality products and adhere to emission standards. When managing and reducing the temperatures for clinker coolers and other equipment, cement plants can increase capacity and production output. Grinding processes are optimized while the cement can be safely conveyed and stored.

Our Applications

Gas Cooling Applications: Evaporative and Bypass Cooler

Evaporative and bypass cooling towers have fabric or electric filters that may become damaged or experience a reduction in service life due to hot gases. Twin fluid spray nozzles or spillback systems can cool gases to limit excess gas creation, prevent material buildup, and provide higher separation efficiency. Cement plants may see lower maintenance costs, reduced clogging for heat exchangers, and large turn-down ratios.

Gas Cooling Applications: Downcomer Duct

Lechler spray nozzles can also be installed within the downcomer duct to help increase production outputs when using alternate fuel sources. Nozzle lances may also protect downstream components from high temperatures, prevent caking and material build-up, and help relieve the induced draft system.

Gas Cooling Applications: Cyclone Preheater

Above the top cyclone of the preheater, spray nozzles can be installed to provide subsequent duct or GCT cooling. Spray nozzles also help to reduce gas flow rates, which lowers the amount of energy that the downstream fan uses to cool off the gas. This setup helps to further protect downstream equipment from overtemperatures while reducing the heat recovery at the top cyclone.

Gas Cooling Applications: Clinker Cooler

Cement manufacturers can install spray nozzles as an additional means to cooling downstream filters leading to clinker cooler processes. In some instances, using only air is not sufficient to create the necessary operating conditions. With spray nozzle cooling processes, gas volumes become reduced while increasing the capacity of the clinker cooler.

Gas Cooling Applications: Ball and Roller Mill

During the grinding process in the creation of cement products, excessive heat can decrease the material's quality. Spray nozzles can manage overtemperatures to dissipate the excess heat while also providing more stability to roller mill grinding beds.

Choosing the Right Nozzle

For gas cooling and conditioning, selecting the right nozzle for your processes will depend on your equipment setup and production goals. That’s why we offer a wide variety of single fluid and twin fluid spray nozzles and lance systems with different materials and anticlogging systems.

For many years, nozzles and spray systems for environmental gas conditioning have been an integral part of our product portfolio. Our constant communication and knowledge with operators of cement/lime plants mean that we are always in tune with the latest developments. Extreme environmental conditions exist in the production of cement and it is very important to use materials that are highly resistant to these types of settings. Contact us today to discuss your process requirements and our nozzle solutions.