Spray Technology for Power Generation Industry

Improving your process with better nozzle technology

Improving Your Process with Better Nozzle Technology

Spray technology for the power generation industry focuses on reducing excessive gas emissions, controlling generated nitrogen oxide (NOx) levels, making downstream equipment more efficient, and removing sulfur dioxide (SO₂) from exhaust flue gases. Improving emissions and making equipment operate at proficient levels ensures that power generation companies can supply the energy that commercial operations and residential homes need. Learn more about the benefits of this spray technology and how it helps with NOx control.

Benefits of Spray Technology in the Power Generation Industry

Power generation companies create substantial amounts of NOx, SO₂, and other flue gases during internal combustion processes. When gas temperatures, humidity, and gas volume are not controlled properly, excessive amounts of these gases are created that can harm the environment when released as exhaust. Additionally, power generation processes produce sludge build-up, which can damage downstream equipment and reduce machinery efficiency. This issue results in unexpected downtimes and increased operational costs until systems can get back on track.

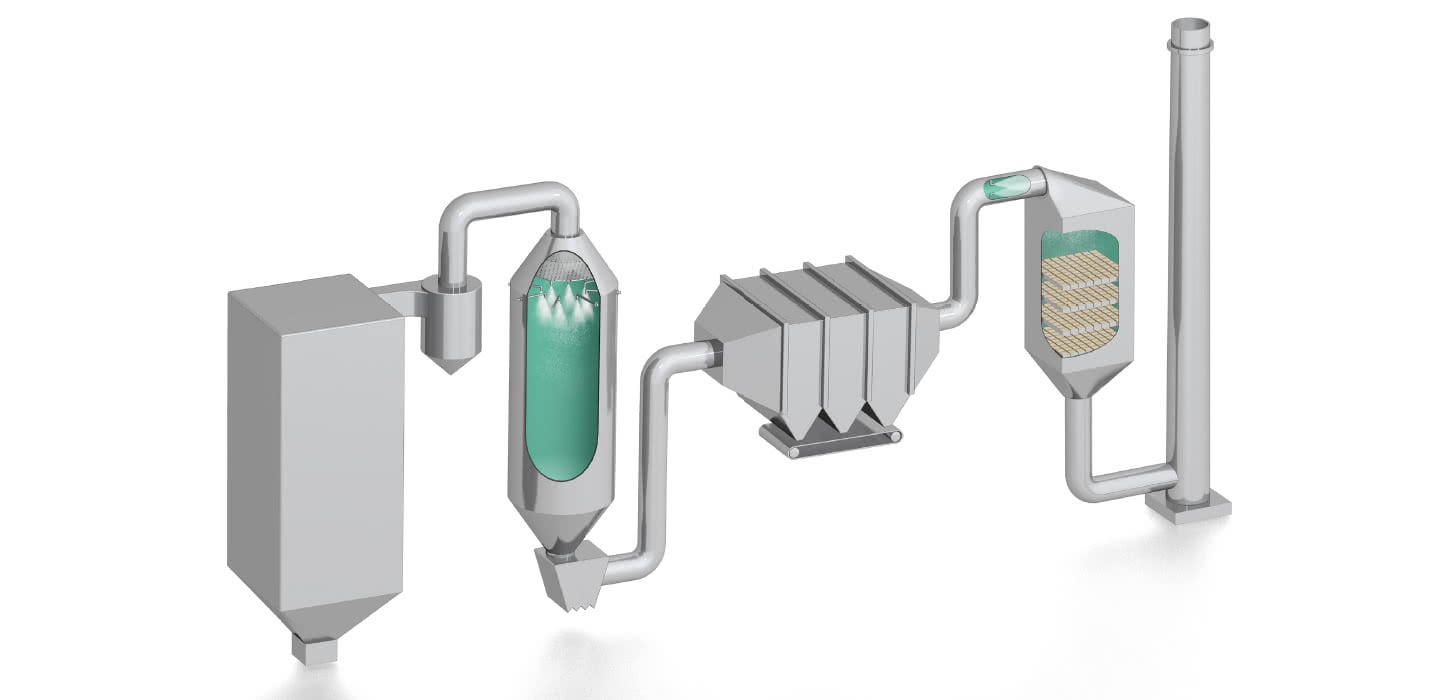

Spray technology makes operations efficient in various ways. This technology, in the form of water spray nozzles, fuel spray nozzles, and cooling spray nozzles, can lower gas temperatures and reduce the amount of gas produced that ends up as flue exhaust. When operations create too much of these toxic gases, processes need to be slowed down until emissions reach safe levels. The spray technologies help to minimize the frequency of this situation, ensuring that processes continue to run at full speed. With operations running daily, it helps reduce unnecessary maintenance and downtime costs.

More power generation companies are also turning to water jet sprays to deal with wetting and sludge buildup. When sludge accumulates in pipes and equipment, it forces the components to labor more, prematurely wearing down parts. Rinsing down the deposits into the bottom of tanks prevents the sludge from entering other processes, leading to an increase in production output.

NOx Control

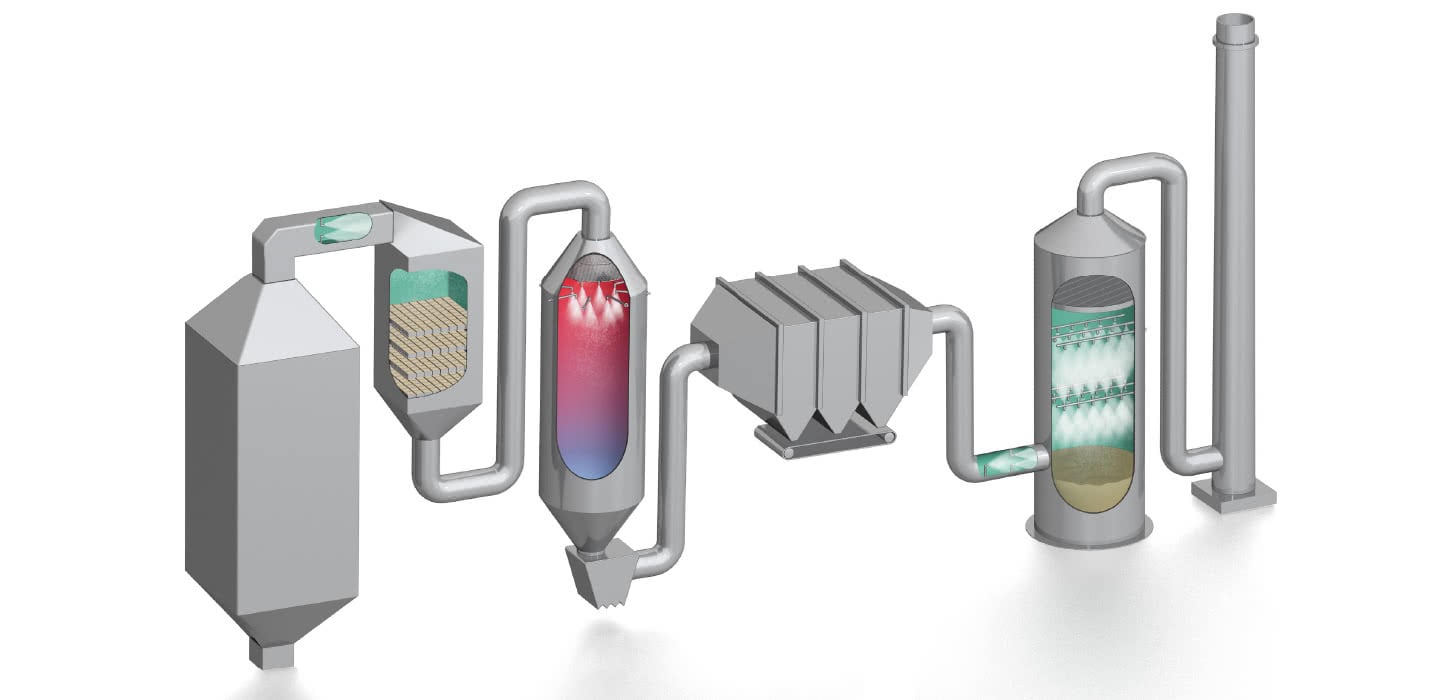

When fuel is combusted to generate power, it forms the byproduct nitrogen oxide (NOx). This nitrogen oxide is considered a pollutant that can negatively harm the environment. Spray technology for the power generation industry helps to control the amount of NOx by using a technique called mist atomization.

Mist atomization involves the use of spray nozzles with precisely controlled distribution, angle, and velocity of aqueous ammonia droplets, along with specific droplet sizes to create a catalytic reduction of NOx. Reducing NOx as exhaust helps to protect outdoor air quality and ensures that plant operations comply with established environmental protection standards.

Contact Us

At Lechler, we offer a variety of spray nozzles to accommodate power generation processes. Our advanced spray solutions are designed to improve efficiency, reduce emissions, and enhance the overall performance of your operations. Learn more about our solutions by contacting us today.

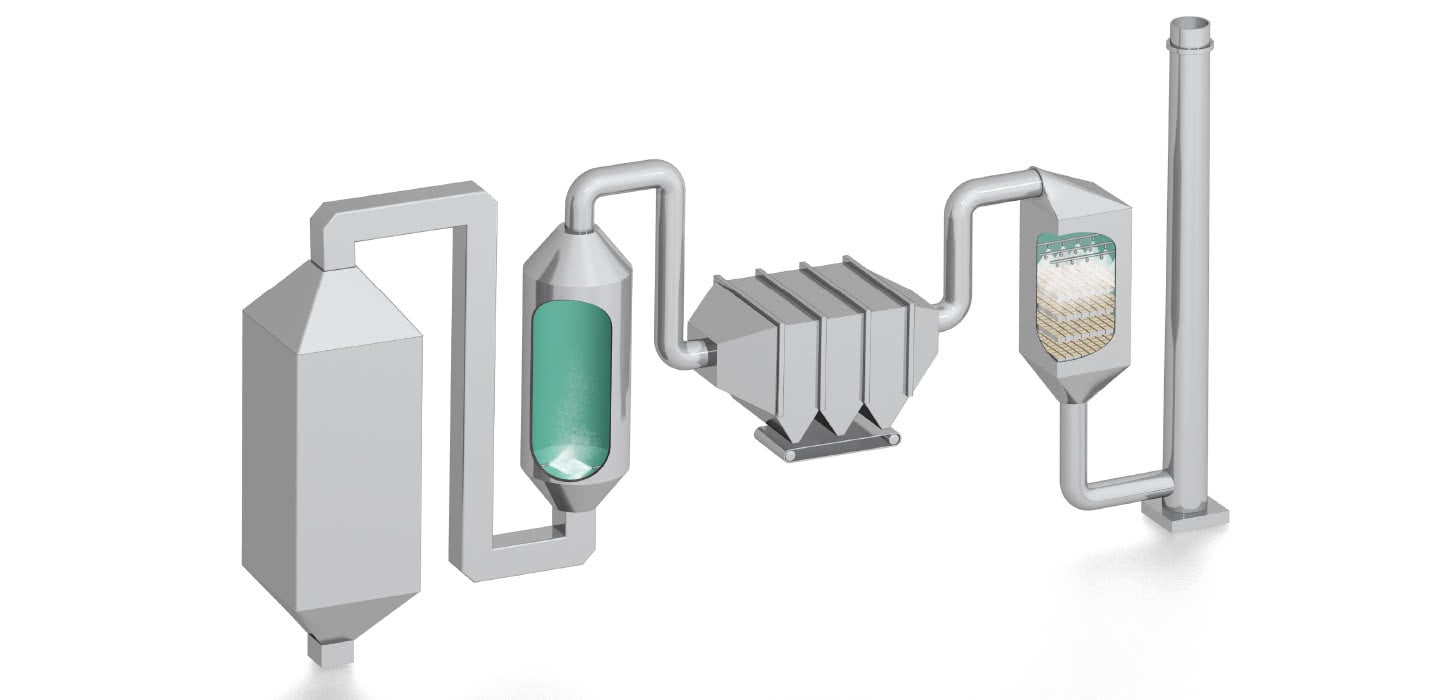

Lechler applications in the power generation industry at a glance

Further Lechler applications in the power generation industry

Further Lechler applications in the power generation industry