New steel grades, wide range of casting speeds and higher susceptibility to cracking due to increased demands...

these are some of the challenges the billet and bloom casters of today are facing. These issues place a high demand on the secondary cooling system of the caster and therefore require more flexibility.

In order to help our customers with these challenges, our research and development team engineered a flexible solution that included:

- Large turn-down rations to accommodate the different types of products to be casted

- Stable spray angles

- Adjustable liquid distribution

- Adjustable cooling performance

Our solution…

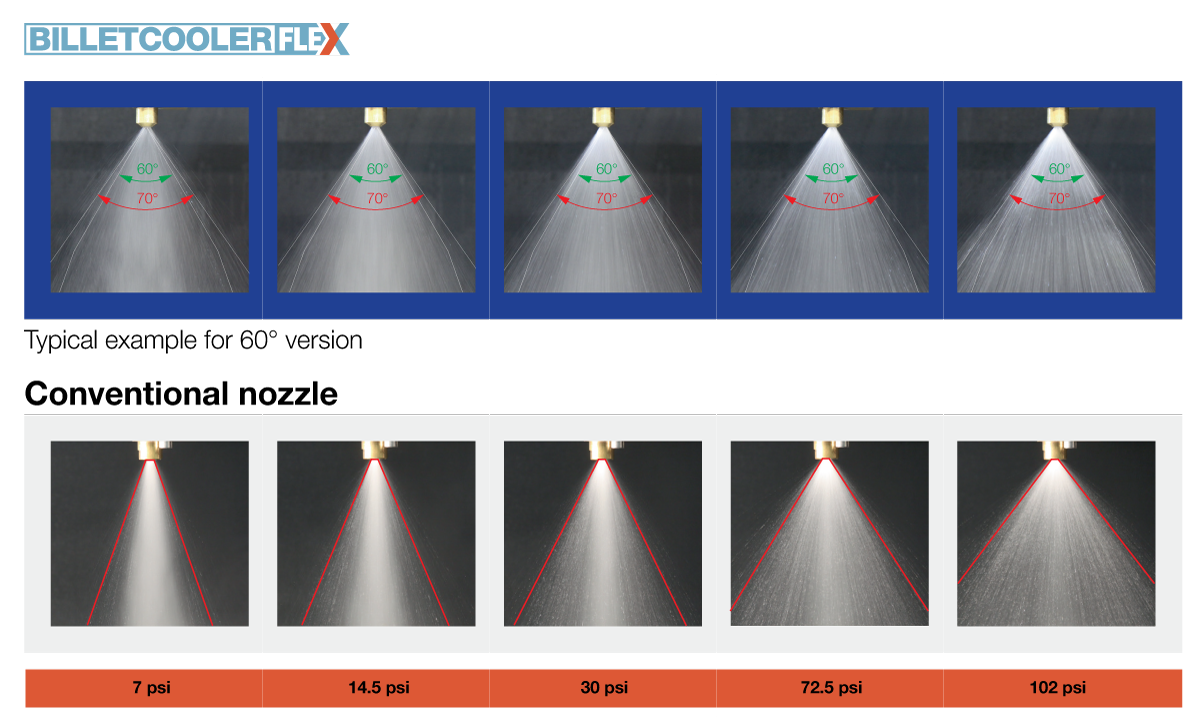

The Billetcooler Flex® is designed with the capability to have a constant spray angle over the entire turn-down range. We offer three different nozzle sizes, each with a turn-down ratio (min./max. water flow rate) of 1:10.The images below represent the comparison of the Billetcooler Flex vs a conventional nozzle.

This nozzle is able to adjust its distribution and cooling performance based on the operating parameters needed.

It can produce a “High Center distribution” needed for billet casting. Cooling performance is concentrated in the middle while preventing overcooling on the edges.

It can produce a “Flat Center” or even distribution geared towards larger bloom casting. Cooling performance is even across the product face.

It can also produce a “Low Center” or concave liquid distribution ideal for rounds. Cooling performance wraps around the product face applying even distribution.

Due to its very large free cross-sections for air and water, the BilletCooler FLEX is clog resistant and maintenance-friendly.

This nozzle requires less compressed air than simpler air-mist nozzle designs and therefore helps to improve the energy efficiency of the overall installation saving you money on operating costs.

Learn more about BilletCooler FLEX