A Hidden Cleaning Solution for Eliminating Spray Shadows

One particularly costly area of tank cleaning involves spray shadows, areas within a tank that are improperly cleaned. Without the right equipment, manual labor is required to remove soil in those areas. One possible solution to this problem is Lechler's 5P5 "PopUp Clean," read more to find out why.

Tank Cleaning Difficulties: Spray Shadows

Spray shadows, or areas within the tank that are hard to clean, occur when tanks have internal obstructions such as agitators, baffles, coils or mixing blades.

Here are some recommendations that may help you overcome these tank obstructions:

- Remove the obstruction before cleaning. In order to accomplish this you will need to make this part of your SOP that includes removal, reinstallation and a COP system for proper cleaning.

- Position multiple tank nozzles in different locations to avoid spray shadowing. For these cleaning tasks, Lechler offers rotational tank cleaning nozzles.

In this video, three rotational nozzles are placed inside the tank. You can see the line of spray being obstructed by the agitators but when multiple nozzles are used they compensate for the shadowing effect to provide complete spray coverage.

A Hidden Cleaning Solution: Series 5P5 “PopUp Clean” Nozzle

Although placing multiple nozzles inside a tank helps avoid spray shadowing, greater challenges such as cleaning underneath the agitators or blades can be very difficult.

For this task, Series 5P5 “PopUp Clean” nozzle is specially designed to eradicate spray shadows, ideal for cleaning agitator blades, along with other difficult-to-reach surfaces inside the tank. Typically, these objects or surfaces would be cleaned manually. As mentioned, this is both dangerous and costly. Manual cleaning is costly because it is labor-intensive and time-consuming. Eliminating manual cleaning dramatically reduces time spent in the tank cleaning process.

Once installed, the PopUp nozzle remains flush inside the tank wall, remaining hidden during the production cycle. This prevents the nozzle from any contamination. During the cleaning cycle, however, fluid pressure causes the nozzle to protrude out of the wall inside the tank. The targeted areas can be sprayed up to distances of 9ft. When the cleaning cycle is complete, the nozzle will retract back inside the tank wall, remaining hidden again.

Consult with us

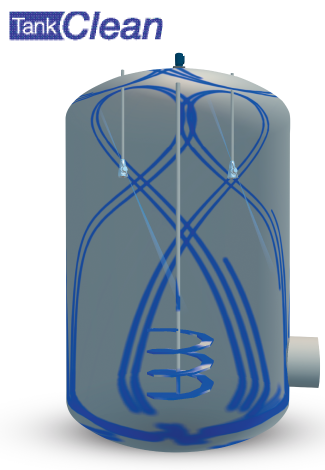

We utilize a tank cleaning simulation software which allows you to plan for your tank cleaning. To do this, we replicate the tank shape in the software and then simulate the spraying operation. Operation of all Lechler tank cleaning nozzles can be simulated – from the static spray ball to the high-impact tank cleaning machine. The result of the simulation is documented and provided in a PDF or video file. Simulation with TankClean can already be used as the basis for optimum cleaning in the planning phase of new tanks, but is also suitable for optimizing existing tank cleaning processes.