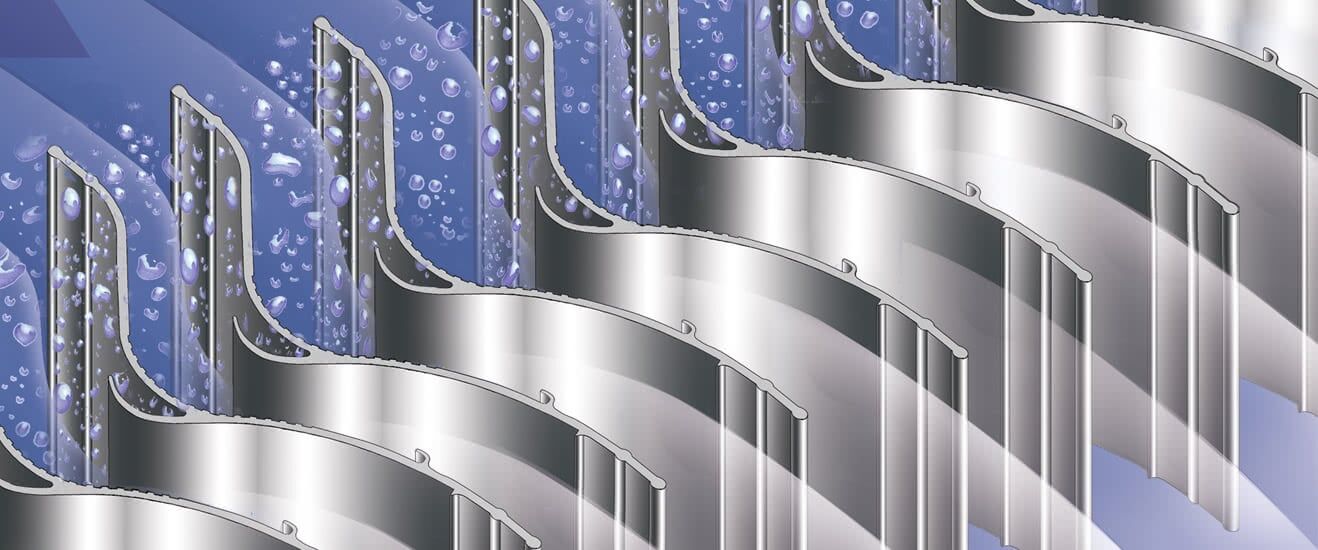

Mist Eliminator Systems

Mist Eliminators for Liquids and Gases

Mist eliminators have long played a vital role in many process operations and in gas washing plants. Mist eliminators have become especially important considering the imposition of ever more stringent environmental protection regulations that necessitate a drastic reduction in the pollutants carried by the gases leaving gas-washing plants.

Such regulations make it necessary to install high-performance Mist eliminators that, while generating as little pressure loss as possible, are capable of arresting even the finest droplets, often with a diameter of less than 10 µm. Working closely with plant operators and with scientific institutes, Lechler has developed a variety of eliminators, which have proved to be highly successful in many fields of industry:

- in reducing environmental pollution from existing plants

- in gas-washing installations

- in the chemical industry

- in the paper and pulp industry

- in air-conditioning and ventilation systems

- on offshore rigs

- in cooling towers and evaporative condensers

- wherever finest droplets must be effectively separated out of vertical gas streams

As each of these applications has individual requirements, Lechler's Eliminator Systems are customized solutions.

Our products

Modular, compact, combinable and efficient.

The different Lechler Mist Eliminator Systems can be combined with each other, depending on individual requirements in relation to efficiency and space.

Functions

- Removal of sulfur compounds

- Protection of downstream plant components

- Reduction of operating costs

Advantages

- Modular design of the systems

- Highest separation efficiency for large liquid volumes

- Separation of small droplets

- Compact design even at high gas velocities

- Low pressure losses

- More uniform flow distribution

- Use also with high solid particle quantities

- Cleaning during ongoing operation

- Delivery of an overall concept

- Nozzles for the desulphurization of flue gases

- Mist Eliminator Systems

- Integrated cleaning systems for droplet separators

Custom-made Mist Eliminator Systems

It is necessary to the design and planning of Mist Eliminators to have a good understanding of the process in which the Mist Eliminator will be incorporated as well as a thorough understanding of the function and performance of the various separation systems. It is of great importance when designing a Mist Eliminator to have an understanding of how droplets are generated and of how they are transported in a flow of gas.

We can honestly say that we know as much or more in this respect than any other, for we have been engaged in the detection, measurement and definition of droplets for more than 130 years. It is not without reason that Lechler Mist Eliminators have become such essential alements in almost every field of process engineering.

The mist eliminators can be produced in a wide variety of designs in the materials stainless steel, plastic or aluminium. They are supplied as ready-to-install components or individual lamellae.