SELECTOSPRAY Roll Cooling Systems

Systematic roll cooling

SELECTOSPRAY – an indispensable actuator for shape control. It corrects reliably asymetrical strip shape defects and supports work roll bending.

To date, more than 300 Lechler SELECTOSPRAY roll cooling systems have been installed globally in cold rolling mills for steel, aluminium and non-ferrous metals, as well as in aluminium hot rolling mills and foil mills. Profit from our comprehensive know-how in this specialist area.

The principle

To achieve precise cooling control, the roll barrel is ‘divided’ into zones, each of which has coolant precisely applied to it by MODULAX valve controlled spray nozzles. Each of the zonal sprays can be operated independently of the others either manually, by push button control, semi automatically by a PLC, or automatically in connection with a shape control system.

The SELECTOSPRAY system can be used in conjunction with any of the shape control systems currently available, the roll zoning being dimensionend to exactly match that of the shape metering roll involved. Zone widths for both automated and manually controlled systems are available, widths in general use being between 25 mm and 100 mm.

The SELECTOSPRAY system includes complete headers, air hoses and control cabinet.

Lechler competence and expertise

Of paramount importance for any roll cooling application is how the sprays impinge on the roll surface. An effective and precise footprint geometry is the fundamental requirement to establish a uniform cooling from top to bottom work rolls and transversely across the cooling area resulting in an optimal heat extraction across the spray cooling area on the roll.

When designing a spray header Lechler arranges the sprays without interference or creating hot and cool bands in adjacent cooling zones. The nozzle flow rates and spray angles are taken into account besides the positions of the spray headers in the mill for the design of the optimal nozzle offset and impingement angles in order to obtain the best heat transfer.

Selective, customer-specific developed roll cooling system

Selective, customer-specific developed roll cooling systemLechler SELECTOSPRAY valves

The proven Modulax valve design is available in three different versions:

- Pneumatically controlled with the solenoid in the control cabinet outside of the mill

- Electro-pneumatically with the solenoid directly attached (DSA)

- Purely electrically controlled (EVA)

All valve versions have very large coolant entry ports, are easily removable from the header front and are protected by the header itself. All valves carry self aligning flat jet nozzles.

SELECTOSPRAY – Systems and valves for selective roll cooling

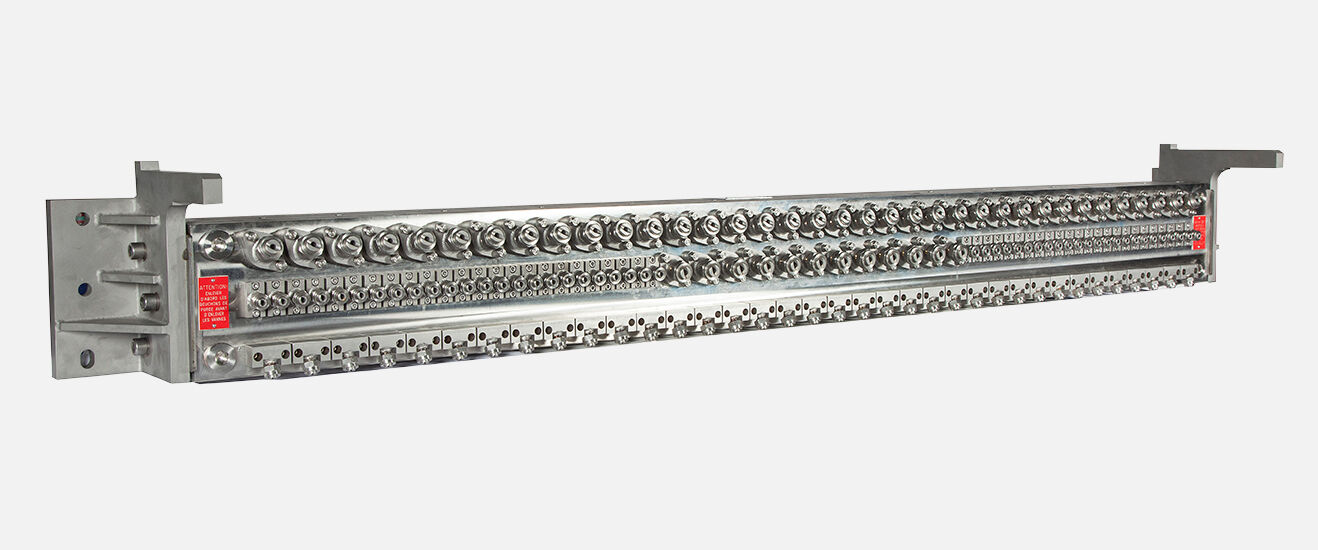

SELECTOSPRAY spray headers

- Customized spray header construction

- Prefabricated standard components

- Robust welded stainless steel construction, forged if necessary

- Application of the latest 3D design programs

- Volume flow and spray angle designed for the positioning of the header

- Spray header have symmetrical cooling for upper and lower rollers in the rolling stand

- Constructed and manufactured for all roll conditions

SELECTOSPRAY control cabinet

- Design of the control cabinets depending on valve type

- Cabinets are custom-made in-house

- Hardwired from remote I/O

- Wago unit I/O is optional

- Interfaces with Profibus / Interbus / Foundation Fieldbus etc. digital interfaces

- HMI consoles for more sophisticated functions are available

SELECTOSPRAY Pneumatic Air Hoses

- Robust stainless steel braid with air lines enclosed in an inner SS convoluted shell

- Pneumatic hoses made for the Modulax and Mini Modulax valves

- Types: 21-way, 30-way, 44-way

- Ø 3 mm air lines for 21-way

- Ø 4 mm air lines for 30-way and 44-way

- IP67 hose end rating

- Key locating fixtures ensuring correct hose alignment

- Custom-made Lechler product

SELECTOSPRAY MODULAX

- Liquid to air pressure ratio 2:1

- Very large internal free passages

- Uses standard shop air

- Simple design, only one moving part which is the piston

Electro-pneumatic valve actuation (DSA)

- Each valve has its own dedicated solenoid directly attached

- Shorter response time

- Air for the pilot operation is fed by a single tube directly into the header and instantly available when the electrical solenoid is activated

- Solenoids can be supplied in either normally open or normally closed

Electric valve actuation (EVA)

- Especially in rolling mills where inflammable rolling oil or kerosene is used as a coolant and without the need for compressed air

- Large orifices for a laminar flow and a stable spray