Providing uniform cooling across the roll width with optimal thermal distribution is essential for achieving a higher quality product. To help our customers attain this we offer a 6 step distribution study. This study delivers a wide range of benefits by determining the improvements that can be obtained with an upgraded cooling system through improved operation and maintenance practices. The study also identifies problems and causes which were previously not recognized. Below is an outline of each step and a brief description.

The first step in helping our customers starts with understanding your mill objectives and defining expectations of your roll cooling needs. For this first step our team of experts will setup a meeting with you to learn more about your process.

Gathering all of the necessary information is a critical part to ensure that we can find a solution to the your problems or needs. Once we have collected all of your data our engineers will begin to analyze your current roll cooling configurations.

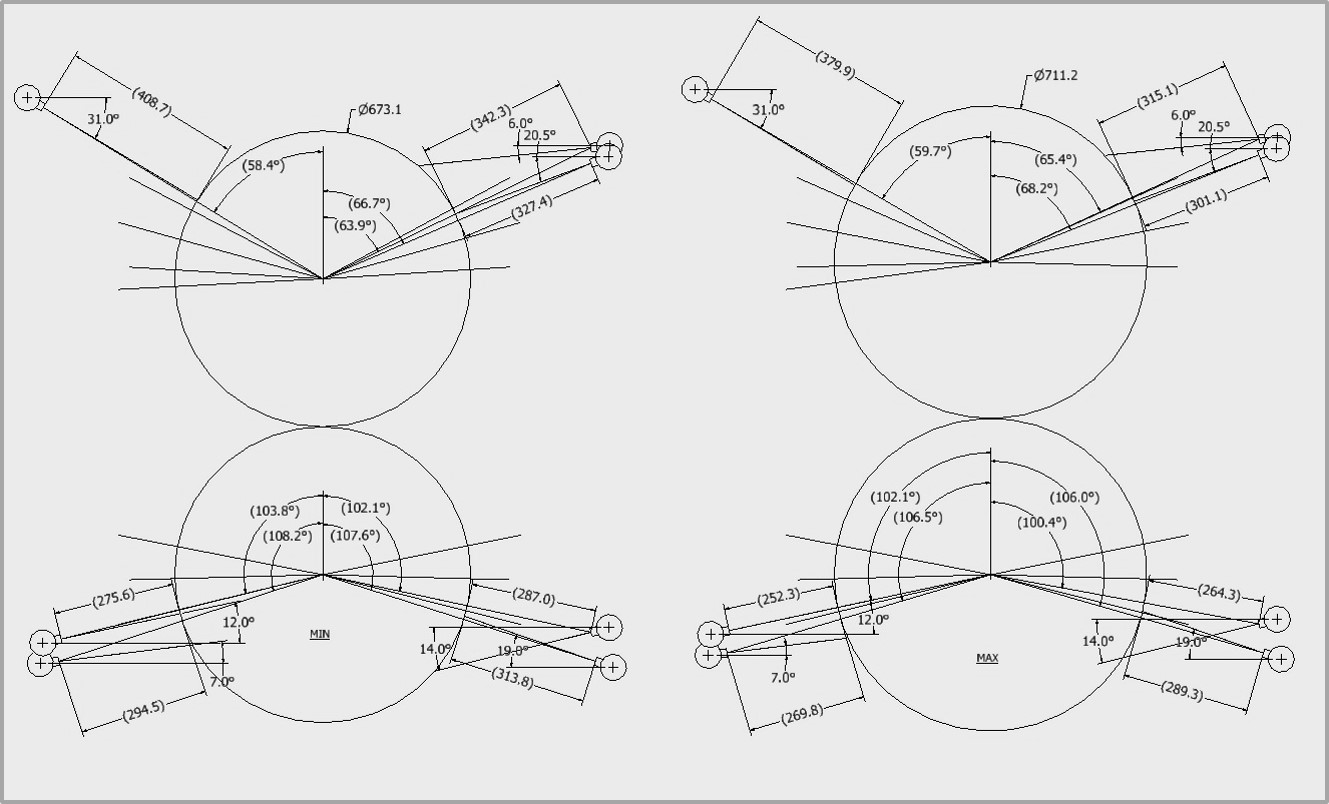

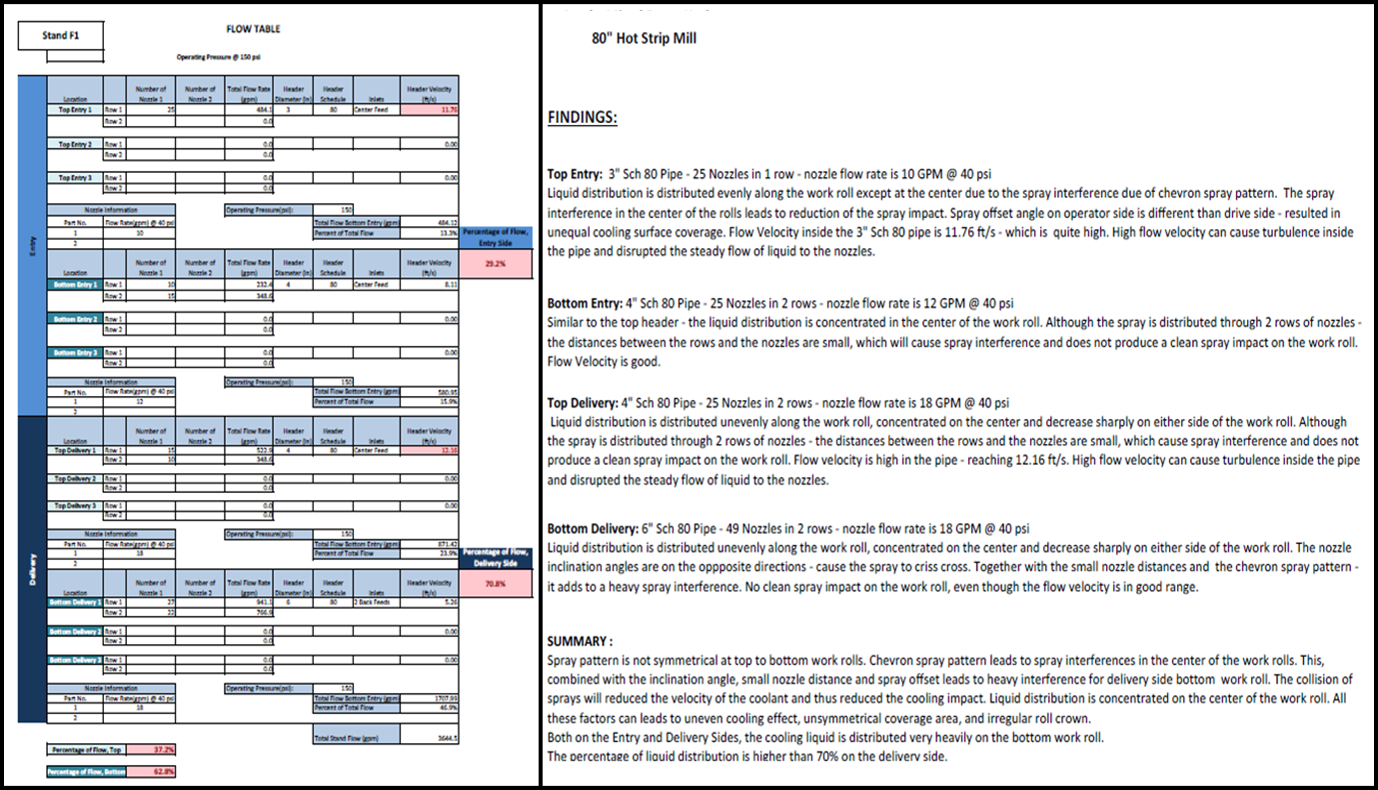

Our engineers will then begin analyzing and processing all of your information into our parametric model. This will help us determine the correct positioning of the header in each mill stand.

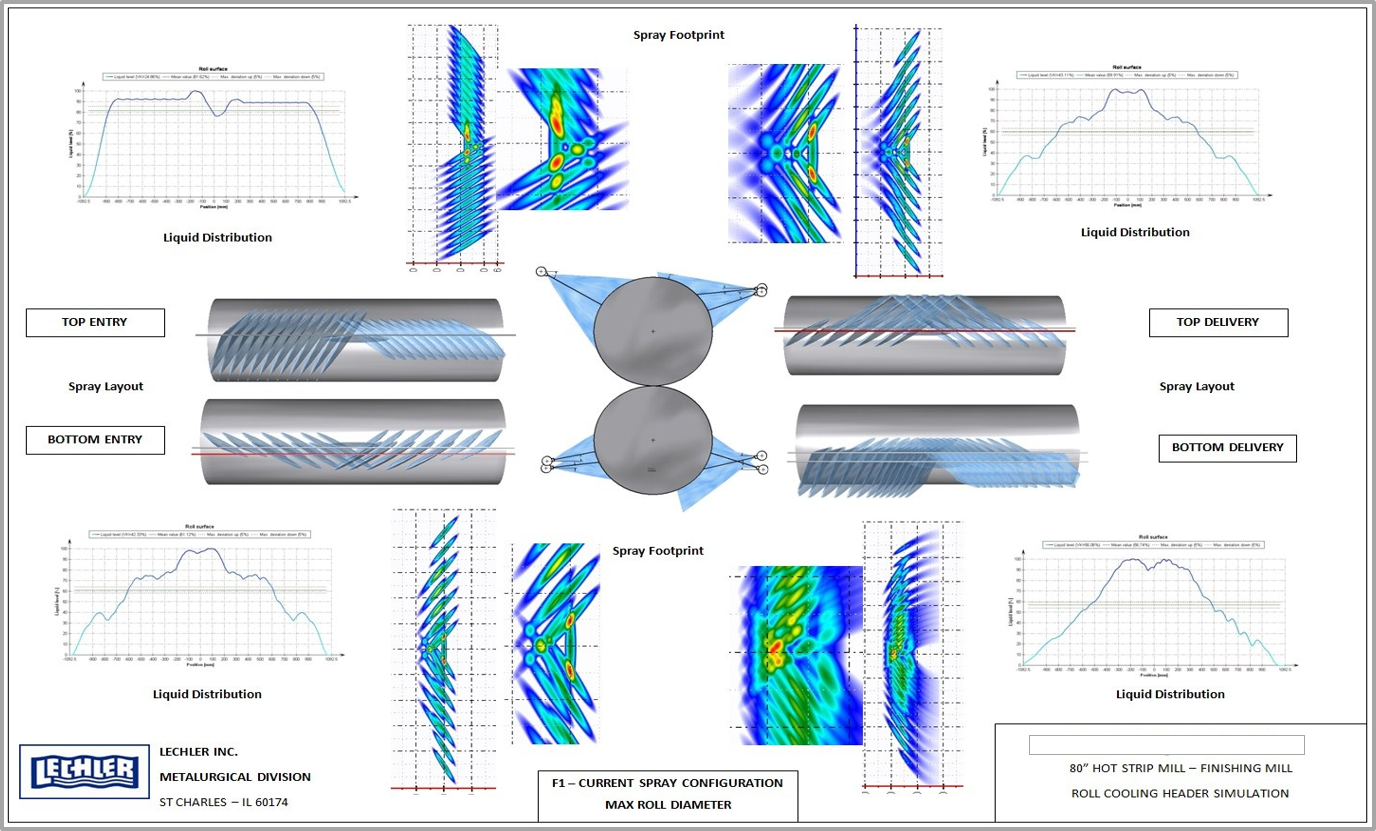

Utilizing our special software and modeling tools, our experts will create simulations to find the best cooling distribution on the center and work rolls.

Once our spray experts have analyzed all of the data and simulated the most effective solution we will create a report with all of the findings and distribution analysis.

Finally we will present all of the findings along with what we feel is the best solution to help you achieve better product quality.

Lechler understands the importance of a high quality product, our spray experts are ready to help you every step of the way.