We live in a society where foods and beverages are produced for mass consumption. These processed foods and beverages accommodate the lifestyles of many families. For this reason, automated equipment must be used in order to keep up with processing and packaging such high volumes.

For Production Managers, this means greater production and reduced downtimes, which leaves little room for error, especially where food safety and quality are critical. Recent laws like the FSMA (Food Safety Modernization Act) make sure that companies not only follow good manufacturing practices (GMP’s) but they remain compliant.

Stainless steel tanks, ovens, and conveyors are all used for processing foods and beverages but these come with many options in various shapes and sizes. Equipment manufacturers typically do not design equipment with accessible cleaning in mind. Equipment must often be disassembled by the operator to ensure that every surface area is properly cleaned and free of contaminants. This can be time consuming and often dangerous for employees but there are other options that can be considered.

Aftermarket products, like spray nozzles provide solutions for process equipment cleaning and sanitizing. Spray nozzles automate the cleaning process and ensure complete coverage for cleaning surface areas. Spray nozzles can reduce water consumption, precisely clean surface areas and increase production times because less time is spent manually cleaning. The aftermarket installment is worth the investment and overtime will pay for itself.

Determining which nozzle is best for cleaning your equipment is subject to the type of equipment being used and what must be cleaned. Food and beverage plants will use various types of processing equipment to produce the final product from start to finish.

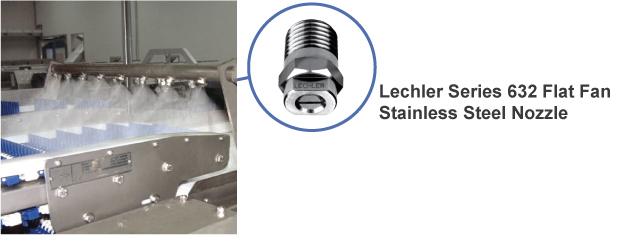

Conveyor Belt Cleaning

Conveyor belts are commonly used for material handling and as excess dirt and bacteria builds up over time, belts can be difficult to clean. Traditional cleaning methods include power washing; however, this process uses excess water and chemicals. A spray manifold with flat fan nozzles can automate the process and provide reliable cleaning results. Flat fan nozzles provide good spray impact and overlap for complete coverage. The spray manifold is typically placed above and below the conveyor, so that both sides of the belt are accurately cleaned.

Tank Cleaning

Stainless steel tanks are widely used throughout food and beverage plants for mixing, blending, storing and fermenting products. The cleaning process can be automated with the right spray device. When selecting a nozzle, tank size and the type of soil being cleaned are very important. Lechler classifies tank cleaning nozzles by cleaning efficiency classes 1 – 5. The chart below is a guide for how to select a nozzle based on cleaning efficiency classes.

When considering a nozzle for cleaning your equipment, our engineering experts can assist you. Lechler is a nozzle manufacturing company with your best interest in mind. We know that choosing the right nozzle will positively impact your bottom line. At Lechler, we will work with you, helping you choose the best aftermarket cleaning solution for your specific application.