Spraying unfiltered media with debris or other solids through your header will cause them to become clogged. This could result in operation shut down costing you time and money. STAMM shower headers are a perfect solution to this challenging task. This shower header is designed with a full length stainless steel internal brush, which is controlled by a wheel positioned at the end of the header. When the wheel is turned, the internal connected brush rod assembly sweeps past the nozzle orifices and helps unclog debris. The wheel also opens a flushout valve so all of the material gets swept out of the pipe without ever shutting down the sprays. Close the valve and you’re back in operation, it's as simple as that!

STAMM® Header Features

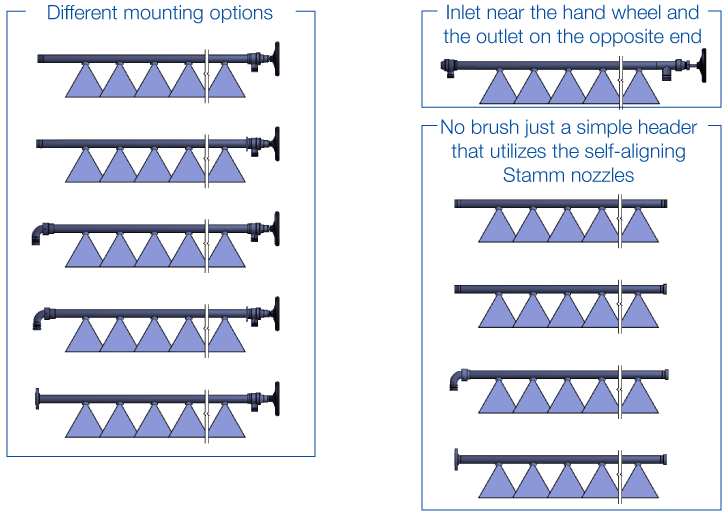

STAMM® Header Variations

STAMM® headers can be made in a wide range of standard profiles to suit specific requirements.

STAMM® Accessories

Automatic Cleaning Device – 10.900

Automatic operation of cleaning device (turning of brush simultaneously opens / closes dirt discharge valve) by means of electric drive motor, resulting in uniform nozzle cleaning.

Oscillator Options Available

> Oil-hydraulic

> Electromechanical with crank-arm and linear spindle

> Pneumatic