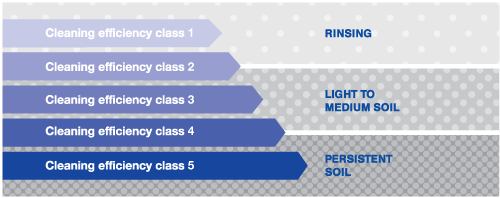

In the distillery industry, equipment cleanliness goes hand-in-hand with the quality of your spirit. Whether you are cleaning your mash cooker or fermentation tank, you need a reliable product that will maximize efficiency in terms of return, energy usage and time. Lechler offers a variety of spray solutions to help you achieve this. Our nozzles are broken down by 5 different classes, efficiency class 1 represents nozzles for rinsing and 5 is made up of nozzles designed for heavy soiling applications.

Below we break down which nozzle is best for cleaning each piece of equipment.

Also referred to as Mash Tun or Mash Tub, when the cook is complete in the Mash Cooker, the mash or wort, which is a sugar rich solution is ready to be converted to Alcohol. The wort is then pumped into a fermentation tank where it is held at a desired temperature. Cleaning the mash cooker can be challenging due to burnt or caked on soil from the coils. For medium to smaller sized tanks, Lechler recommends products in our cleaning class efficiency 3 or 4 and for larger sized tanks, Lechler recommends products in our cleaning class efficiency 4 or 5.

Once the wort is pumped into the fermentation tank or fermenter, these tanks are designed to turn the feedstock into alcohol for human consumption. When it comes to cleaning fermentation tanks, positioning is key due to the two rows of cooling coils, which creates a possibility of spray shadows or areas not cleaned from direct impingement of the sprays. For medium to smaller sized tanks, Lechler recommends products in our cleaning class efficiency 3 or 4 and for larger sized tanks, Lechler recommends products in our cleaning class efficiency 4 or 5.

Holding tanks are traditionally used to store distilled spirits before any post processing is done (proofing, blending, and bottling). Washing of your holding tanks or storage tanks is paramount, to ensure cross contamination does not occur in your spirit, . Holding tanks traditionally only need a light to medium wash to ensure no cross contamination persists. For medium to smaller tanks, Lechler recommends products in our cleaning class efficiency 2 or 3 and for large sized tanks, Lechler recommends products in our cleaning class efficiency 3 or 4.

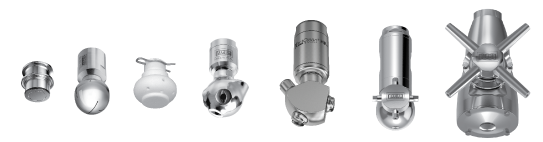

For all of these applications, we recommend rotational tank cleaning nozzles. Utilizing a controlled-rotation nozzle is perfect for high-impact cleaning that consists of stubborn soils to be removed.

The video below shows Lechler's XactClean HP+ which is a controlled rotational nozzles cleaning chocolate sauce off of a tank. These type of devices, produce a cleaning fluid which drives the rotating head, a turbine wheel controls the rotation to ensure that the speed remains in the optimum range at higher pressures. The flat fan blade like nozzle ensures adequate coverage to clean in hard to reach areas.