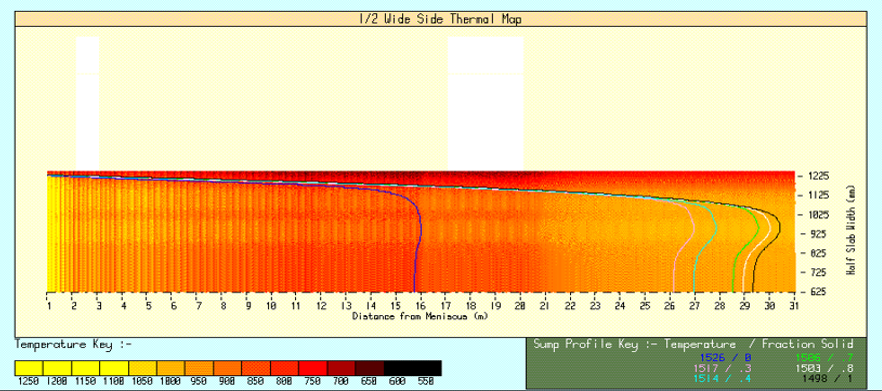

Casting is the first step in steel production; therefore, it is essential that it is optimized. Defects within your casting process will affect the surface quality of your final product. Lechler’s thermal modeling study can provide detailed information on how to modify your existing system, to help increase production, quality and flexibility. Our studies allow us to provide a full benchmark of your current system, and deliverables that are based on your overall scope of supply.

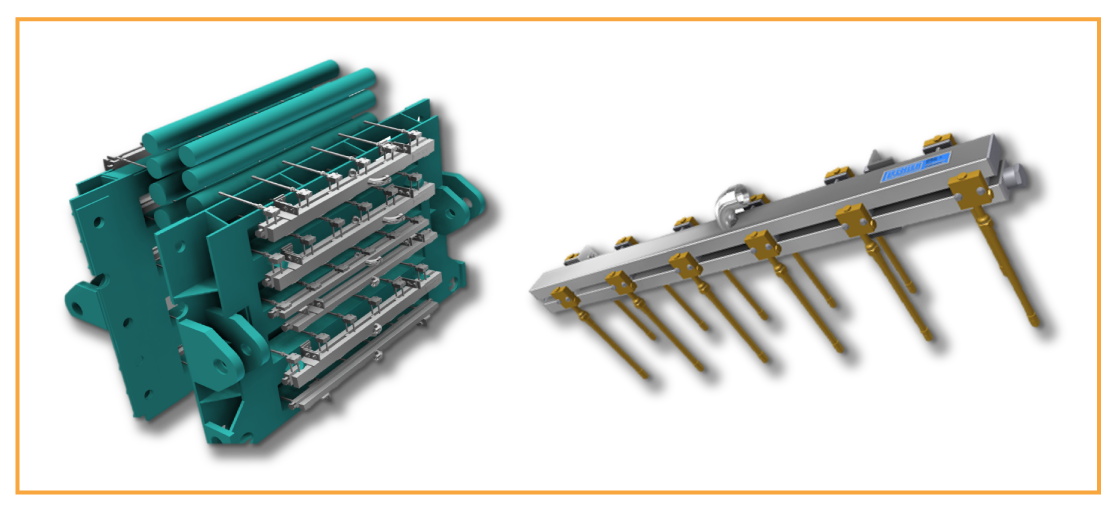

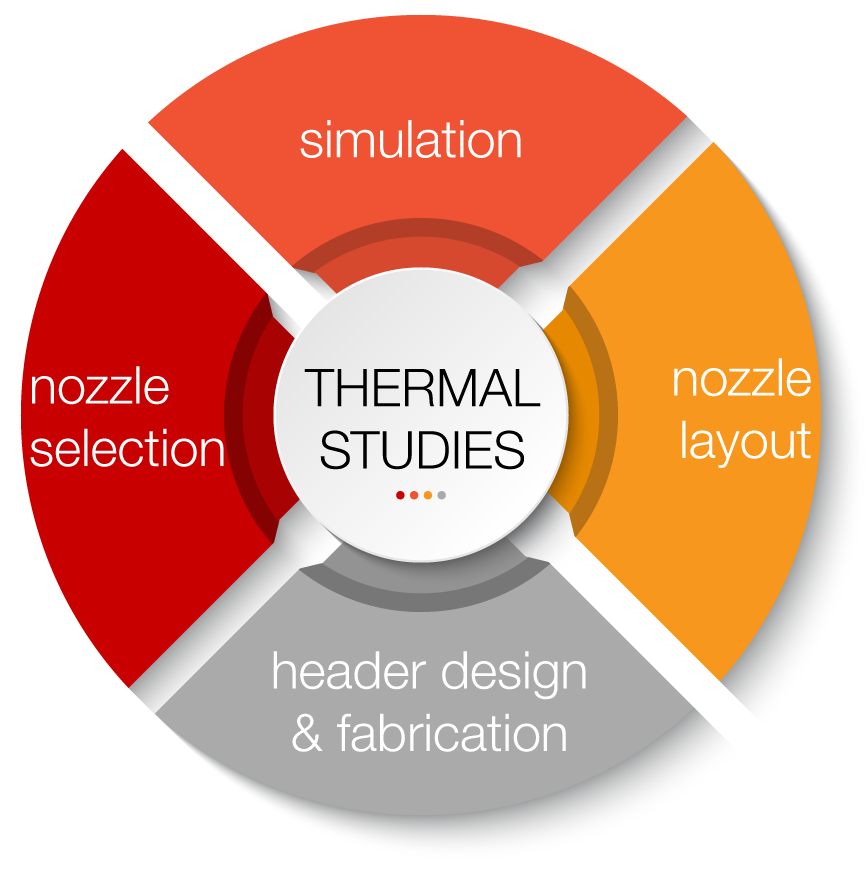

Our study starts by collecting data from your entire process. We then use simulation software to calculate theoretical models. From this data we simulate improvements and determine new nozzle layouts, nozzle design and selection, new header design and fabrication.

- Benchmark current system

- Identify product quality defects and how to eliminate them

- Improve ease of maintenance and reduce cost

- Maximize production by increasing casting speeds

Once we have benchmarked the caster, we will provide a complete report and proposal on improving your process. This includes:

- Report of the full benchmarking of the current process

- New secondary cooling layout, nozzle layout and capacities for the nozzles

- New secondary cooling header design and fabrication proposal

- Max and min flow rates

- Required changes to the supply pipe work

- Secondary cooling control and control data

- Conclusions and recommendations for operational and maintenance practices.