Static or Rotational Spray

Which is best?

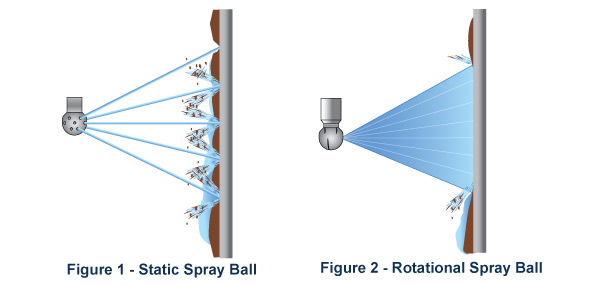

When carrying out simple cleaning tasks in smaller tanks or vessels that require a simple rinse, the fixed or static spray nozzle continues to provide excellent cleaning.

However, “effective” is not always the same as “efficient.” The other areas are only rinsed, in terms of cleaning technology. See figure below which shows the impact of the static spray vs rotational spray. To generate an effective flow for removing stubborn grime, spray nozzles require high volumes of liquid. Even in medium sized tanks (5ft to 10ft in diameter), static systems have limitations. If you analyze the entire cleaning cycle of application, the spray nozzles are not economical. To meet the growing demands of hygiene, plant efficiency and the environment, rotating nozzles are considered a better choice in most cases today.

Application:

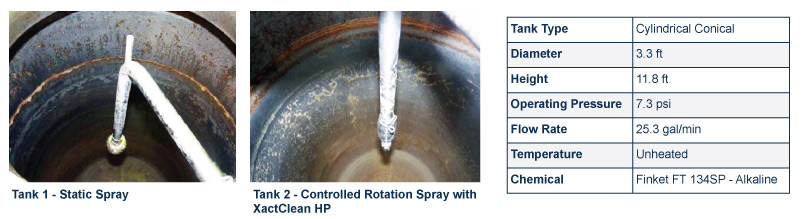

Lechler GmbH in cooperation with Munich University worked in collaboration with Germany to conduct a cleaning evaluation tank test between static spray and rotational spray. The test results were presented a the World Brewing Congress in 2016.

The initial test was setup in a pilot brewery using 2 fermentation and storage tanks. Each tank was filled with the same beer and the fermentation and storage time were the same. Above the filling level there was a sticky yeast residue on the tank surface., which you can see inside the perimeter of each tank.

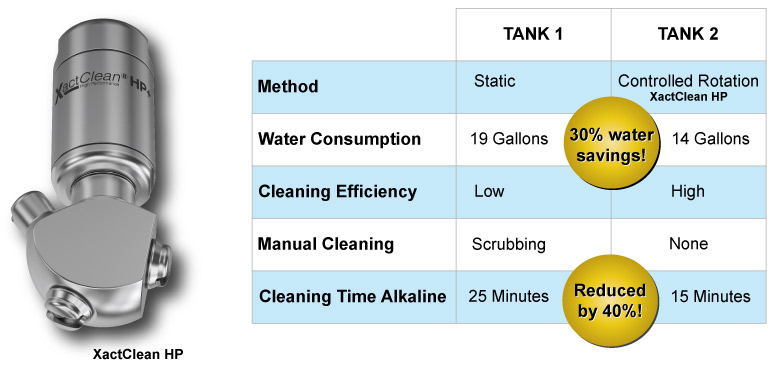

The image below shows tank 1, a static spray nozzle was used as the cleaning mechanism and in tank 2, Lechler's XactClean HP rotational nozzle was used.

Process:

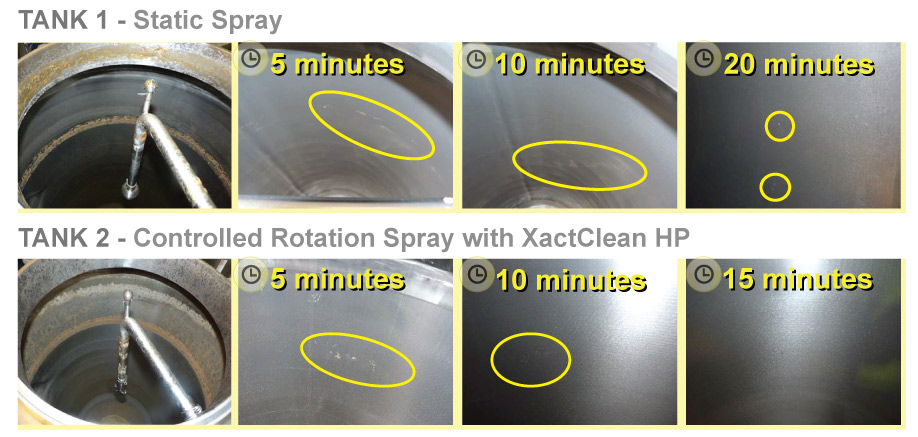

The image below depicts the amount of residue left during each CIP process. The initial step was a 15 second fresh water rinse, and then 2% alkaline was added. The process was stopped and checked every 5 minutes to evaluate the amount of residue left inside the tank.

Results:

This chart shows the overall conclusion of the test. In tank 1, not all of the yeast residue could be removed even after 25 minutes and the test was stopped. The tank required manual scrubbing to remove all the yeast residue left over. In tank 2, all of the yeast residue was removed in 15 minutes by the controlled rotational nozzle.

Rotational Spray Nozzle wins the match

Rotational spray nozzles are able to clean tanks more efficiently. Their flat fan spray pattern penetrates a larger surface area inside the tank with greater impact. The droplets created by these spray nozzles are larger and strike at higher speeds, which enable them to remove tough soil. Rotational spray nozzles use less water, increase production cycles and use fewer chemicals, so that you save money and have less headaches.

Still have questions? We can help!

Lechler's tank cleaning experts are here to help you with every step of the process.