Simple Ways to Reduce Water Consumption

Water conservation is a concerning topic among industrial businesses, who consume large amounts on a daily basis. Manufacturers are focusing on water treatment for reuse and ways to reduce water consumption.

In the content below, we demonstrate how simple reducing water consumption can be – with the proper nozzles. Flow capacity, maintenance, and cleaning processes are each explored in depth.

Choose a Nozzle with Correct Flow Capacity

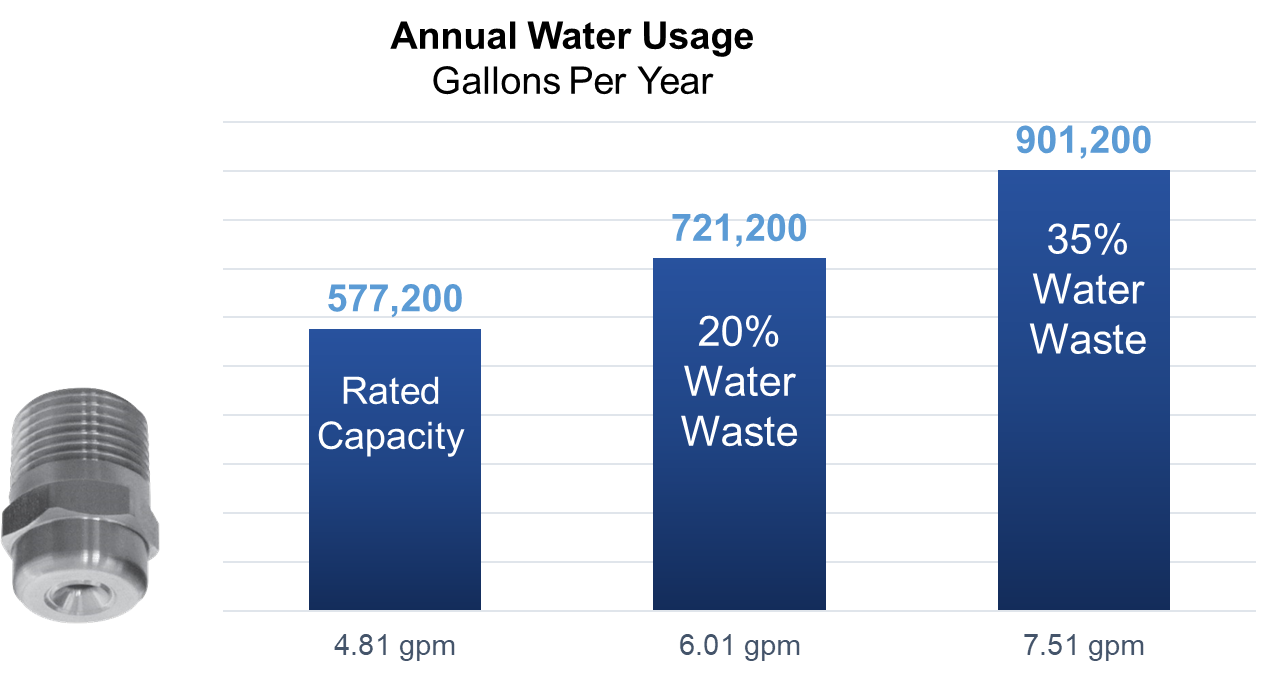

Nozzles are offered in various flow rates and by selecting the proper flow rate, water consumption can be significantly reduced. Consider the following analysis below, which specifies the amount of water of water consumed in one year using the same nozzles and pressure with different flow rates.

In one year, a full cone nozzle rated at a capacity of 4.81 gpm, consumes a total of 577,200 gallons of water.The same nozzle at higher flow rates, will use 20% to 35% more water and as a result more water is wasted in the process. This results in additional cost for water, water treatment and water waste. By choosing the right nozzle for your process, you can benefit from efficiency and additional savings.

Identical ½” NPT connection, Full Cone Nozzle Series 490 with different flow rate capacities spraying @ 40psi. Based on spraying 8 hours/day, five days per week, 50 weeks per year.

Perform Proper Nozzle Maintenance

Proper spray nozzle maintenance enhances spray performance, extends nozzle life, and augments water conservation efforts. Five primary guidelines inform proper maintenance standards. We explore each guideline below:

1. Change nozzle material

2. Add a line strainer or filter

3. Use proper cleaning tools and care

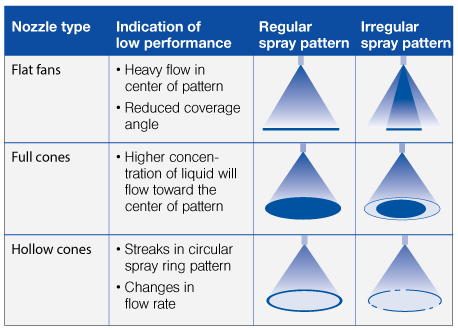

4. Detect irregular spray patterns

Underperforming flow capacity by nozzle type is pictured below:

5. Schedule routine maintenance

Nozzles should be inspected regularly. Incorporate routine maintenance into your standard operating procedure (SOP). Common inspection tasks include checking nozzle alignment, inspecting nozzle damage, checking spray pattern quality, and monitoring changes in flow rate. Nozzle damage takes many forms, including:

Download our Maintenance Guide

Automate Cleaning Processes

Are you cleaning manually or utilizing static spray devices? Both practices are red flags, inhibiting optimal performance. Manual cleaning is time-consuming, expensive, and dangerous. Static spray devices provide sufficient equipment cleaning for minor cleaning jobs, such as rinsing. However, static spray devices require more water to adequately clean than other nozzle varieties.

Lechler offers a full line of rotational spray devices