Improve your tank cleaning efficiency and save more with precision engineered nozzles

Your cleaning process may require using higher temperatures for sanitizing and aggressive cleaning solvents for removing difficult soils. If you’re not using the proper mechanics for cleaning, you may be spending more time and money as a result. In this article, we will explore the Four Main Factors of Cleaning, theimportance of mechanics and how this can result in significant cost savings.

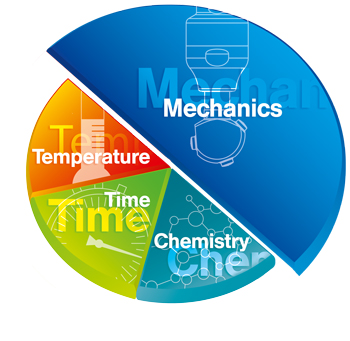

Four Main Factors of Cleaning

Effective cleaning involves four main factors: Time, Mechanics, Chemistry and Temperature. The proportion of the individual factors as a part of the entire cleaning process can be varied, provided that the total is 100%. We’ll take a look at each of the four factors and how they can affect the cleaning process.

- Time is the duration of the total cleaning process and this can be reduced or increased depending on the other 3 factors.

- Chemistry is the cleaning solvent being used for removing the soil. Depending on the type of soil, more aggressive cleaning solvents may be required for removing difficult soils from the surface area. These can be quite costly if the duration of your cleaning cycle is long.

- Temperature is the measurement of how hot or cold your cleaning cycle is. Higher temperatures are typically used for sanitizing and these can run up to 160° to 180°.

- Mechanics is the method being used to remove the soil, which can be either manual or automated. This factor can have the greatest impact on reducing cost and time. If the Mechanical factor takes up a greater portion of the circle, less costly aggressive solvents and high temperatures are required because the cleaning cycle time is shorter.

Let’s explore what Mechanics are most effective for cleaning.

The mechanics of Controlled Rotational Nozzles are specially designed for delivering a better spray impact to remove difficult soils. The rotating head is driven by the fluid and the internal gear is used to control the rotation. This ensures that the speed remains in the optimum range even at higher pressures. These nozzles produce large droplets which strike the tank wall at high speeds removing thick soil. Important influencing factors can be the distance between the nozzle and wall, and the operating pressure. If either are too great the fluid will break down into smaller droplets and the impact will be reduced.

XactClean HP+

The XactClean HP+ is designed for providing superior mechanical cleaning action. This controlled rotational nozzle provides uniform cleaning and high impact, thanks to the specially designed flat fan nozzles. The robust drive unit makes the XactClean HP+ extremely dependable while increasing operational reliability.

XactClean HP+ Characteristics

- Maximum temperatures up to 203°F

- Recommended operating pressure 45psi

- Flow rates @ 40psi range from 51gpm to 93gpm

- Nozzle can be installed any direction

After exploring all the features of the XactClean HP+, it’s relevant that the mechanical factor is most important. This results in using less aggressive cleaning solvents and higher temperatures because the cleaning cycle time is much shorter. Carefully selecting the right nozzle saves both money and resources, making your cleaning equipment decision important. At Lechler, we are happy to assist you in formulating a tank cleaning strategy that ensures a flawless process. With 140 years of spray nozzle expertise, we will lead you toward the very best equipment for your application.

Lechler's tank cleaning experts are here to help you with every step of the process.