Spray System for Downstream Injection Chemical Processing

For chemical processing applications, downstream operations may require the injection of chemicals or other liquids at full or diluted concentrations into equipment systems. Downstream processes may also require treatment of incoming gasses in venturi scrubbers or steam in steam exchangers. This is where Lechler comes in with our ideal spray system for downstream chemical processing. Our automated systems are designed to integrate seamlessly into your existing processes to boost efficiency and streamline your applications.

What is Chemical Downstream Processing?

Chemical downstream processing encompasses a range of applications that involve treating liquids, gasses, steam, or other materials based on the industrial application. This processing may involve the injection of chemicals at certain diluted rates. The injection is typically applied using a manual power washer system. However, this process can be time consuming and wasteful.

Pressure drop can occur when using hose-connected handheld injection tools. In addition, spray nozzle distribution can be ineffective for the application and may misapply the solution which can slow down operations. When involved with chemical downstream processing, you want to ensure the proper distribution of downstream chemicals into applications at an even flow rate that can handle varying temperatures and pressures.

Other downstream processes may involve injecting chemicals to separate different liquids in a mixture, to remove particles from gas or air, or to remove heat from steam applications. In these instances, the use of spray nozzles that have various spray designs can ensure high impact and uniform distribution of liquids into tanks or air streams. Placed at specified angles, the nozzles provide full coverage for the best distribution over the desired area.

Common Applications of Downstream Processing

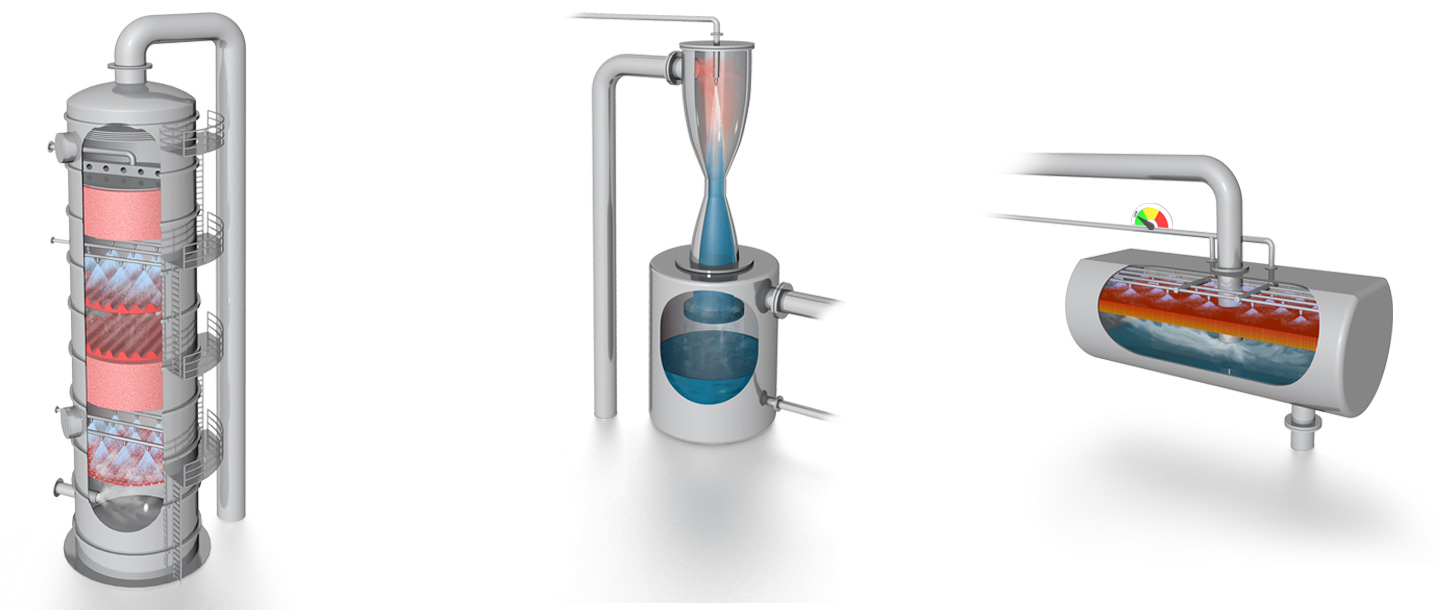

While industrial operations may vary their downstream processes based on their industry, here are some common applications found with chemical processing. They involve distillation, steam condensation, and venturi scrubbing.

Distillation applications separates liquid mixtures for distillation. Depending on the volatilities of the chemicals, they may be separated by fractions or component parts.

Venturi scrubbing involves removing particles from incoming gas. The gas is piped into the scrubber at high velocities as the spray nozzles atomize the water or other liquid into a fine mist. As the gas passes through the mist, the water clings to the particles and separates them from the gas stream to float down to the bottom of the tank for collection.

Steam condensing is another downstream application where condensers act as heat exchangers to turn hot steam into a liquid state. This application requires spray nozzles that provide optimal spray coverage to impact the entire air stream of steam entering the vessel.

Lechler nozzles are designed for myriad uses in downstream injection and other chemical processing applications. Whether used to separate particles from liquid, air, or gas streams, used for heat exchanging, or needed for tank washing and cleaning, our nozzle designs can accommodate your operations to provide cost-effective solutions. Reach out to us today to learn more.

Examples engineered solutions | Examples spray nozzle solutions |

Nozzle lances and injectors

Pump and control skid units

| Tangential full cone nozzles - series 422/423

Full cone nozzles - series 403/405

|

Contact

For additional products, please refer to suggested literature.