Nozzles and Engineered Upstream Chemical Solutions

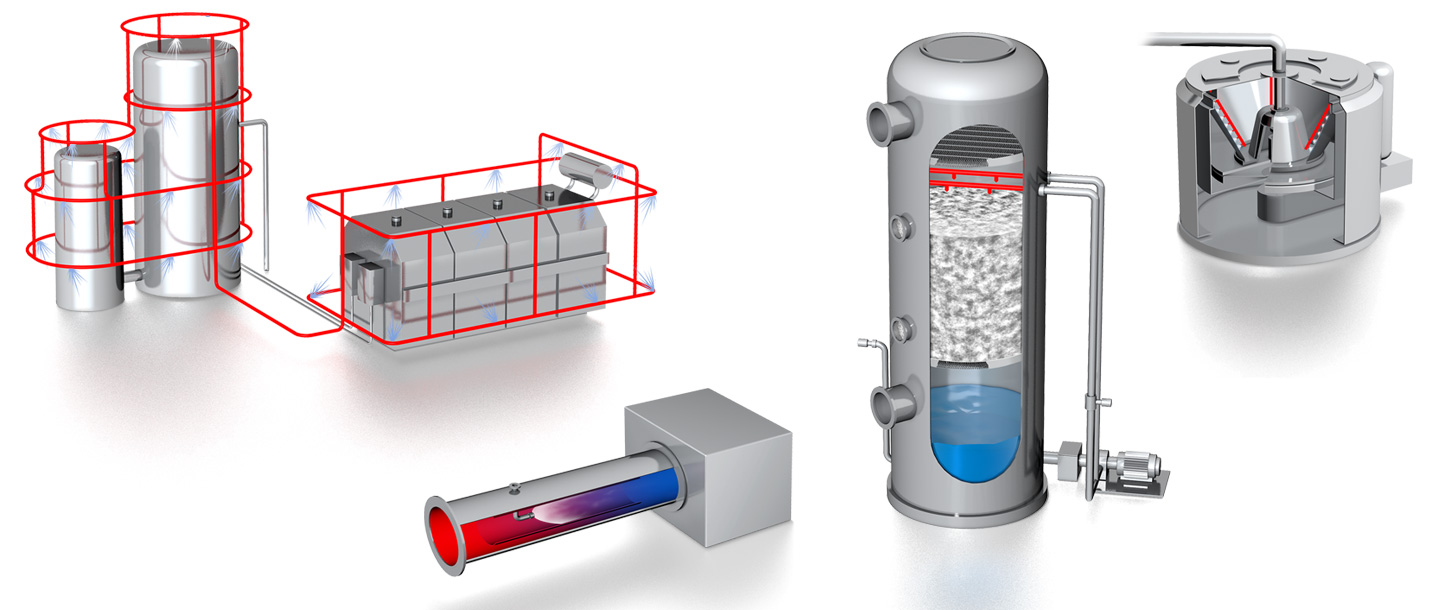

Examples engineered solutions | Examples spray nozzle solutions |

|---|---|

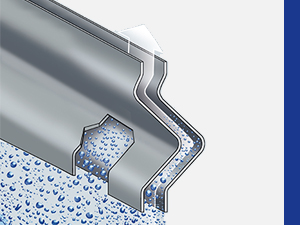

Mist eliminators

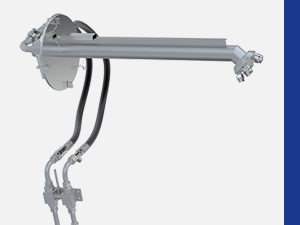

Nozzle lances and injector

| Full cone nozzles - series 490

Twin-fluid nozzles

|

Spray System for Upstream Chemical Processing

Chemical processing plants rely on water and chemical systems in different production lines. Water may be used for various safety systems, such as fire suppression and dust control, as well as cleaning purposes. Chemicals must move efficiently through processes and into waiting truck or storage tanks, as well as evaporation ponds. To control water and chemical pressure while minimizing waste, a spray system for upstream chemical processing becomes vital for these operations. Here at Lechler, we offer spray nozzles and engineered spraying solutions for industries involved with chemical processing.

Waste Reduction Benefits of Spray Systems for Upstream Chemical Processing

Spray systems need to direct water or chemicals in specific amounts for upstream processes. Often it is inefficient to simply drill a hole into the pipe to release the liquid. This type of application would lead to massive waste, since the water or chemicals could not be controlled by the operator. Also, droplet sizes and flow rates would be inconsistent, which may lead to insufficient coverage and waste.

Spray systems from Lechler improve the efficiency and effectiveness of upstream processes. These solutions can produce the finest droplets suitable for processes without pressure loss while accommodating high flow rates. The droplets ensured even coverage and uniform sizes to help conserve resources.

Common Upstream Chemical Applications

Chemical applications vary based on the upstream systems employed by the company. Here are some common applications where these spray systems can bring advantages.

Fire Suppression

Fire suppression systems need to direct water in case of indoor fire hazards caused by flammable liquids igniting. These systems are designed to sense heat and/or smoke from flames in the vicinity.

Dust Control

Indoor dust may enter processes, hampering working equipment and chemical products. Misters, foggers, and other types of spray systems may be used to capture floating particles and bring them to the ground.

Truck/Tank Cleaning

Chemical residues can stick to trucks and tanks, which could contaminate other products placed inside. Spray systems can be used for truck and tank cleanings to wash all surfaces thoroughly to remove every trace of remaining chemical.

Heat Exchanger Cooling

Heat exchangers use water or coolant to move heat from processes or from the building and transfer it to another location where the heat can be dispersed or used. Spray systems are used in heat exchanger cooling to pull the heat from water and place it into exhausted air or back into processes.

In addition to these applications, a spray system for upstream chemical processing may also be used for upgrading froth control, evaporation ponds, and wastewater control operations.

Lechler Spray Solutions for Chemical Processing

In the world of upstream chemical processing, finding ways to optimize efficiency and yield is always a top priority. One important tool in this pursuit is the use of a spray system, which can help to evenly distribute chemicals and control reactions. Our engineered spray nozzles and systems can be used in a variety of processes.

Contact

For additional products, please refer to suggested literature.