Nozzles and engineered solutions for basic chemicals

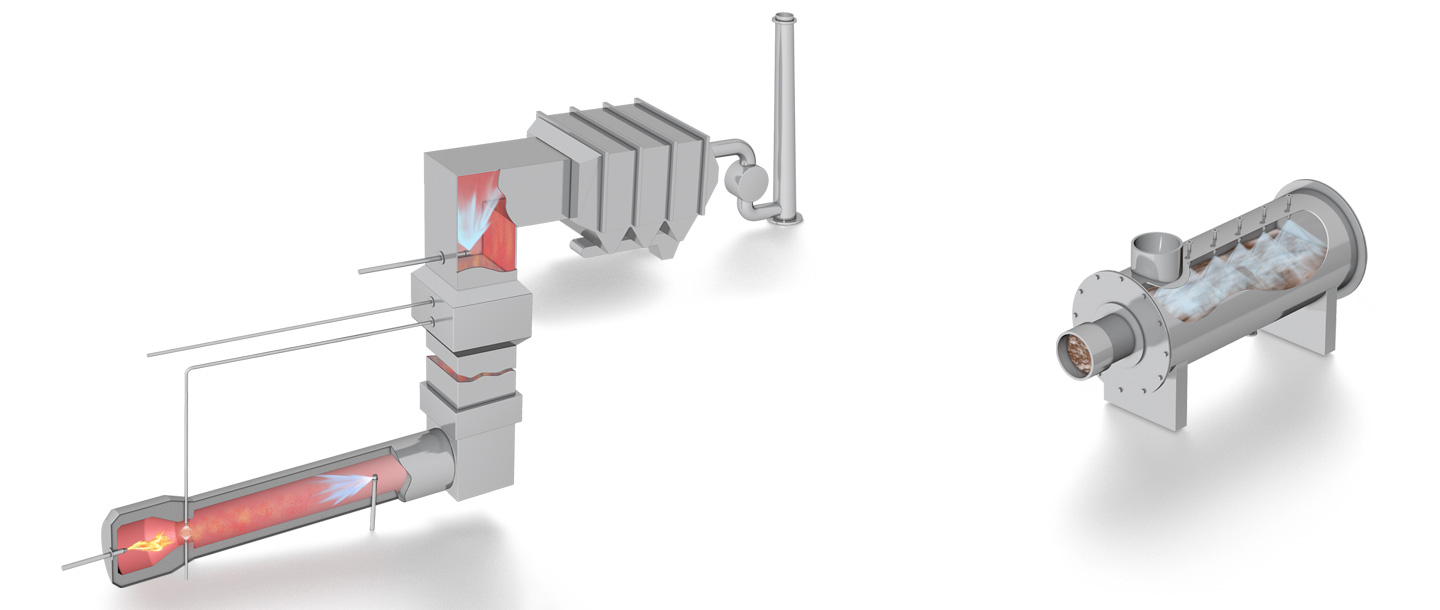

Examples engineered solutions | Examples spray nozzle solutions |

Nozzle lances and injectors

Pump and control skid units

| Hollow cone nozzles - series 214/216/218

Twin-fluid nozzles - series 170/180

Twin-fluid nozzles – VarioJet

|

Contact

For additional products, please refer to suggested literature.