Bacteria and contamination can be prevented by keeping your equipment properly sanitized. For many food and beverage companies cleaning can be a challenge because of the various types and styles of equipment offered by equipment manufacturers. Most equipment requires manual cleaning but there are some designs, which already come installed with automated CIP systems.

Depending on the type of equipment that is being cleaned manually, consider automating your cleaning process with spray nozzles. Spray nozzles provide an effective method for cleaning food and beverage equipment. Equipment with existing spray devices can also be improved if you’re not satisfied with your cleaning results. The engineering experts at Lechler have over 140 years of experience in designing sprays for cleaning and sanitizing applications.

Spray Nozzle Considerations for Manual Cleaning

Manually cleaning with power washers is not the most effective cleaning method because large amounts of water and solvents are consumed during this process. Excess water on production floors can cause workers to fall and injure themselves in the cleaning process. Spray nozzles can be used in place for various types of equipment that needs to be cleaned.

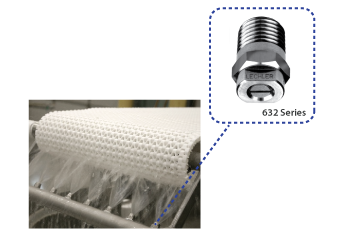

Cleaning Solutions for Material Handling Equipment

Conveyor belts are used for material handling and belts must be periodically cleaned. By installing a spray bar both above and underneath the belt, the cleaning process can be automated. Lechler’s flat fan nozzle series 632 provides excellent spray impact and coverage for removing difficult substances. This type of spray solution requires less time than manual cleaning and provides accurate and precise cleaning results.

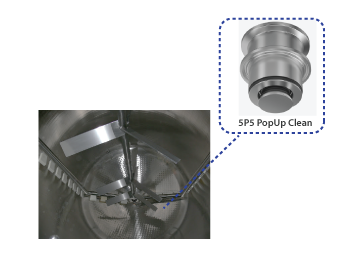

Cleaning Solutions for Agitators & Mixing Blades

Obstacles inside vessels, such as mixing blades and agitators can be a challenge to clean because of their location. For this reason, engineers at Lechler specifically designed the PopUP Clean nozzle. The PopUp Clean is installed flush inside the tank wall and with a fluid pressure of approximately 15 psi in the supply line; the nozzle automatically pops out of the housing and begins to spray. Surfaces that were once difficult to reach can now be cleaned because of this specially designed nozzle.

Improving Existing CIP Spray Systems

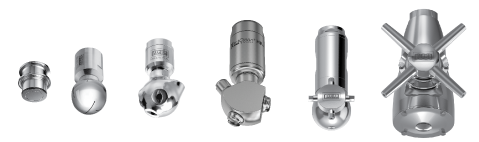

Food and beverage processing equipment and vessels or tanks may already be equipped with a current spray device. The most common spray device placed inside equipment is the static sprayball. Static sprayballs are very traditional nozzles but they may not provide enough spray impact or coverage for the type of soil be cleaned. These cleaning nozzles were originally designed for a light rinse and do not provide complete coverage for all surfaces that need to be cleaned. Engineers are using newer technology to develop rotational spray devices, which provide better mechanical action and complete spray coverage. Consider upgrading your current spray device with a nozzle that has greater mechanical action for removing difficult soils.

Rotational Spray Cleaning Devices

Lechler offers a wide range of tank cleaning nozzles with various designs and operating principles for different cleaning requirements. Our nozzles are capable of rinsing to removing the most difficult soils. Learn how to select the right tank cleaning nozzle for your cleaning application.

Engineering Your Spray Solution

Lechler works closely with equipment manufacturers and customers to develop nozzles for process specific applications. We have over 25,000 nozzles varieties and all of our products undergo research and testing. Our engineers understand spray technology and we are more than just a nozzle manufacturer.