Bacteria is one of the most prevalent dangers in the food and beverage industry. Owners know the importance of maintaining a clean, sanitized tank. Standards and guidelines should be established and more importantly followed to ensure product quality. These are 5 helpful tips for keeping your tank clean.

Employee safety should always come first and although the traditional method of cleaning tanks is done manually, it can be very dangerous. Today, tank cleaning nozzles have become very popular for cleaning tanks and for a good reason! These devices can be mounted inside the tank where the process can be automated, so that employees no longer have to climb inside tanks with a pressure washer to clean. This avoids the risk of anyone falling and injuring himself while inside the tank. More importantly, with an automated process you can be assured that your cleaning results are accurate every time!

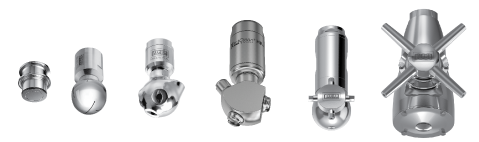

You can benefit from water consumption, chemical usage and cycle time by choosing the right nozzle for cleaning your tank. Nozzles are characterized by four different operating principles, as shown below.

Let’s Explore the differences…

- Static nozzles are primarily used for rinsing.

- Free-spinning nozzles are fluid driven. These nozzles are designed for removing light soils in small to medium sized tanks. When compared to static, these nozzles use less water in shorter periods of time.

- Controlled Rotational nozzles are used for removing medium to heavy soils. An internal turbine controls the rotation of the nozzle so that even at higher pressures the speed is maintained.

- Gear-Driven nozzles contain internal gears and the spray head rotates on two axes. These jets sweep the entire tank surface to ensure complete spray coverage.

Rotational nozzles provide better impact, cleaning coverage and require less time than static.

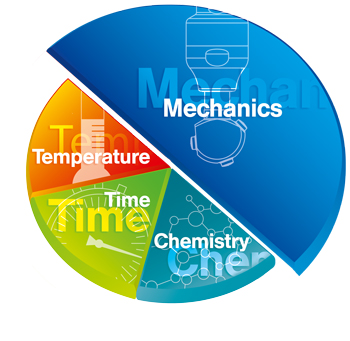

There are four basic fundamentals of tank cleaning and each one of these can have an impact on cleaning.

- Chemistry simply refers to the type of chemical cleaning agent used during the tank cleaning process.

- Temperature refers to the temperature at which cleaning is performed.

- Time indicates the total duration of the cleaning process.

- Mechanics indicate the spray method by which soil is removed.

Mechanics will have a greater impact as shown in the diagram below, if rotational tank cleaning nozzles are used. Rotational nozzles are far superior in reducing water consumption, chemical usage and cleaning cycle times.

It is important to identify areas inside your tank that are problematic for cleaning. Nozzle placement is critical for this task and if not properly placed inside the tank, surfaces could be neglected. For this reason, engineers at Lechler developed TankClean, a simulation software that finds the optimal solution for nozzle placement. Operation of all tank cleaning nozzles can be simulated. In some cases, more than one nozzle may be required for the cleaning task.

Agitators and mixing blades located inside the tank present another cleaning challenge because of their location. The PopUp Clean nozzle was specially designed for this task. The PopUp Clean nozzle remains flush inside the tank, so that it can be placed in areas that are difficult to clean. The nozzle pops out of the housing upon fluid pressure and flat jet sprays provide powerful impact for cleaning.

Remember that a clean tank is just as important as other processes in production and maintenance operations. A routine tank cleaning process should be part of your standard operating. Instead of manual cleaning, consider automating your process with a rotational spray device. These considerations can make all the difference in your sanitation program, leaving you with improved cycle times, reduced costs and a bacteria free tank.

Lechler can help you find the optimum solution for perfectly cleaning your tank by using our TankClean Simulation software. TankClean selects the right nozzle while realistically simulating your cleaning process to find the best cleaning solution for your tank.