Rotating Spray Nozzles

The cleaning fluid turns the spray head by means of specially positioned nozzles. Rapid-repetition impact loosens the dirt and washes it off of the tank surfaces. The effect is best at low pressures in small to medium-size tanks.

Nozzle Series

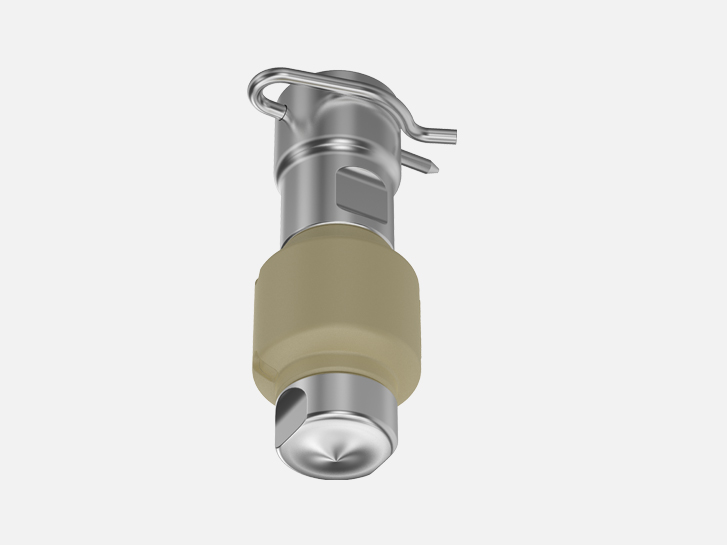

Series 500.234 "PicoWhirly"

The PicoWhirly works with rotating solid jets and is also suitable for cleaning at very high temperatures. This rotating cleaning nozzle with a kolsterized slide bearing is made entirely from stainless steel and can also be used in very small spaces, thanks to its extremely compact construction.

Series 566 "MicroWhirly"

Thanks to the robust bearing made from PEEK, the MicroWhirly has a particularly long service life. The MicroWhirly is alternatively available with an internal or external thread and in an ATEX version, which allows it to be adapted to a wide range of uses.

Series 500.186 "MiniWhirly"

The MiniWhirly made from POM is the economical entry-level model in the area of tank cleaning. The rotating nozzle has effective flat fan nozzles and was specially designed for applications in barrel and canister cleaning.

Series 500.191 "PVDF MicroWhirly"

The PVDF MicroWhirly is made entirely from PVDF and designed to work in a corrosive environment. It is also suitable for contact with food and the application of foam, and can be used for cleaning equipment - all for a very good low price.

Series 5M1 "NanoSpinner 2"

The NanoSpinner 2 has a compact design which allows cleaning in confined spaces. In addition, the rotating cleaning nozzle is characterized by its popular design and a double ball bearing. It is made entirely of stainless steel and is thus also suitable for high ambient temperatures.

Series 5M2 "MicroSpinner 2"

The MicroSpinner 2 has a compact design which allows cleaning in confined spaces. The MicroSpinner 2 is made entirely from stainless steel and designed for use also at high temperatures. It is available with many different flow rates and spray angles.

Series 5M3 "MiniSpinner 2"

The MiniSpinner 2 has a popular design for effective cleaning. The MiniSpinner 2 is made entirely from stainless steel and designed for use also at high temperatures. It is available with many different flow rates and spray angles.

Series 5M4 "MaxiSpinner 2"

The newly developed MaxiSpinner 2 is similar to the Mini, Micro and NanoSpinner series in many respects. As the largest product of this series, it is able to achieve effective cleaning results and is reliable with a durable design due to its bearing construction The MaxiSpinner 2 is made entirely of stainless steel (316L) and is also designed for high ambient temperatures.

Series 573/583 Whirly

The Whirly is of particular interest for applications in the chemical, pharmaceutical and food industries. It works with rotating solid jets and is suitable for use in corrosive environments. The slip-on connection has a 3A certification and can be used in dairy applications.

Series 5P2/5P3 "PopUp Whirly"

When a certain fluid pressure is reached, the rotating cleaning PopUp Whirly nozzle is automatically extended from the enclosure. These free-spinnng rotating nozzles can be installed flush in the tank wall. They are also suitable for cleaning pipes and for applications that use foam. They are of particular interest for applications in the food and beverage industry as well as for the pharmaceutical and chemical industry.

Series 594/595 "HygienicWhirly"

The HygienicWhirly with its highly effective flat jets is particularly suited for hygienic applications and for the application of foam. It can be used to clean tanks and equipment. Operation at low pressure with a good cleaning effect is also possible.

Series 5W9 "Whirly 2"

Popular and proven: the design of the "Whirly 2". The rotating cleaning nozzle generates effective flat jets and offers various connection options. It is available in a very wide range of flow rates and different spray angles.

Series 577 "Gyro"

The Gyro cleans with powerful nozzle inserts and is available in many flow rates and spray angles. It is also suitable for very large tanks and can be submerged without clogging.